Prospect of laser welding in automobile industry

Release time:

2021-05-12

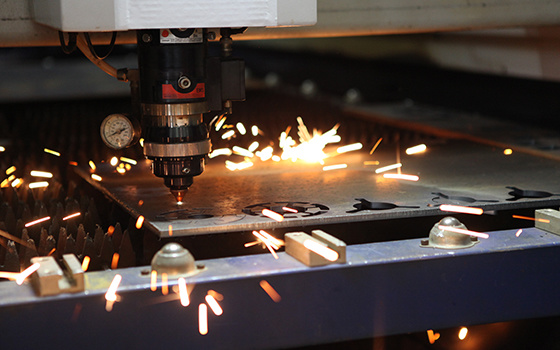

The automotive industry is a production-oriented industry which requires a lot of processing and testing, and also one of the industries in which laser technology is widely applied.Due to the advantages of high processing quality, high efficiency and good flexibility, laser welding technology will be more valued and widely used in the automotive industry with the deepening of the concept of vehicle lightweight and the increasing concept of safety performance.

Automotive is an important field of laser welding

The automotive industry is a production-oriented industry which requires a lot of processing and testing, and also one of the industries in which laser technology is widely applied.Due to the advantages of high processing quality, high efficiency and good flexibility, laser welding technology will be more valued and widely used in the automotive industry with the deepening of the concept of vehicle lightweight and the increasing concept of safety performance.

Aluminum alloy is a very common material in automobile processing, and laser welding technology has unique advantages in welding aluminium alloy.Laser welding enables efficient protection of aluminium alloys.However, there are also some disadvantages in the use of laser welding in aluminium alloy processing, which is determined by the thermal properties of aluminium alloy itself.Although laser welding can effectively protect aluminium alloy components, it can not effectively avoid common phenomena during welding such as spatter of molten pool and collapse of small holes.

With the emergence of automatic driving and new energy technologies, more and more vehicles are equipped with power batteries.As laser welding is a non-contact, high-precision and efficient welding method, it can weld and seal battery structure quickly and economically, and has been widely used in battery manufacturing.Around 19 major component parts including the core, module and pack need to be welded throughout the power battery manufacturing process, of which 11 are currently required to be welded by laser, 5 are possible to be welded by laser, and 3 are not welded by laser.In square-shell batteries, laser welding is used for seals, cover plate assemblies and seals.In cylindrical batteries and modules, laser welded parts are used with poles, caps, manifolds, etc.

In the aspect of module side panel welding, aluminum alloy profiles and plates are commonly used in power battery modules as module outer frame structural parts. The quality of welding determines the rigidity of the module overall structure.Different welding joints and processes can achieve different welding results, and laser welding of side panels has also developed a variety of processes.The porosity of common weld joint is 10%, that of double beam weld joint is 3%, and that of swing spot weld joint is only 1%.More and more advanced laser welding equipment and processes continuously improve the welding quality and reduce the porosity.

In addition, laser welding of core seal is an important process in battery manufacturing, which has a great influence on the yield of battery.While the core welding speed is getting faster and faster, it is also necessary to ensure the weld properties such as uniformity of the weld.A variety of laser welding sealing processes are derived from this.Among them, the high-speed swing welding of the fiber laser makes the welding seam smooth and uniform.The oscillating head can repair the explosion point with the increase of welding frequency.

Power battery is a product with high safety requirement. Battery leakage may lead to short circuit between batteries in the module and fire at high temperature. Cracks and holes in the battery are potential factors for seam seal failure.Therefore, high-quality laser welding is a very critical part of battery manufacturing.

Latest News