How to use fiber laser in power battery industry?Example of side panel welding of battery module tells you!

Release time:

2021-05-12

The so-called power battery refers to the battery used in electric vehicles, which has large storage capacity and output power and can be used as driving power for electric vehicles.

Power Battery

The so-called power battery refers to the battery used in electric vehicles, which has large storage capacity and output power and can be used as driving power for electric vehicles.

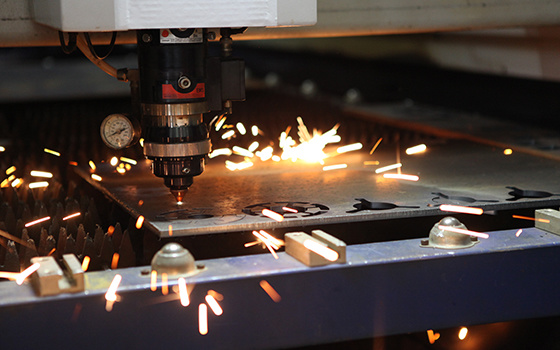

At present, lithium batteries (battery packs) are commonly used in the market, and there are many production processes. Among them, laser welding is required: explosion-proof valve sealing welding, ear welding, soft connection welding, safety cap welding, shell closure sealing welding, module welding, PACK cladding welding, electrode pole welding, bus bar welding and so on. The main materials of the power batteries are pure copper, etc.Aluminum and its alloys, stainless steel, etc.

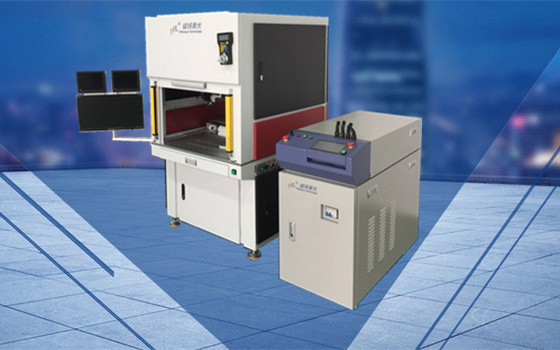

1000W-2000W Welding Scheme

The material thickness of components such as explosion-proof valve, pole ear, safety cap, case seal and electrode pole is generally small, usually between 0.2 and 2 mm. These components mainly require sealing or have low requirements for weld strength. Laser power for welding these components is generally relatively small. Three lasers, 1000W, 1500W and 2000W, can basically meet the requirements.

Latest News