Welcome to the official website of Suzhou Toflylaser Technology Co., Ltd.

Hotline:+86-400-1175-118 Inquiry:+86-13306234535

About Us

Professional laser equipment and automation equipment manufacturer

Win trust with responsibility, develop with innovation

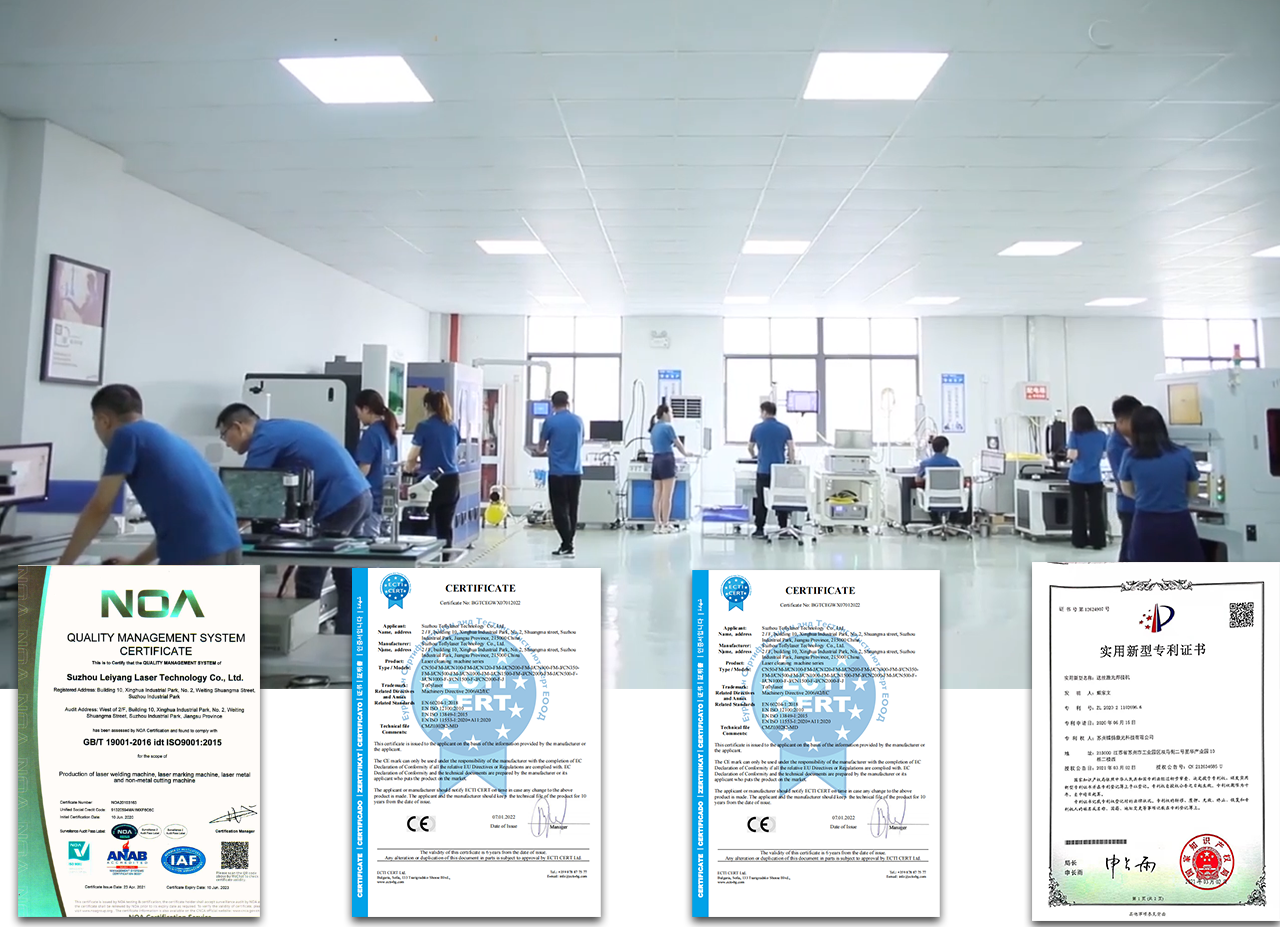

Suzhou Toflylaser Technology Co., Ltd. is located in China’s advanced manufacturing base, Suzhou Industrial Park Xinghua Industrial Park. Our company attaches great importance to technological research and development, employing a group of optical, mechanical, electronic, software development professionals in the field, and has rich experience in green laser, uv laser, picosecond laser and other advanced laser applications and equipment manufacturing.

The company's main industries include medical industry, automotive industry, new energy industry, consumer electronics industry, hardware industry.

Our company has a precision assembly workshop and a number of professional training of assembly technicians, has a strong and flexible manufacturing capacity, annual production and manufacturing of various equipment capacity up to 600.

Technology Deposits

Various patents

Service Experience

Laser workpiece case

Product Show

Dedicated to the research and development, production and sales of laser equipment

Toflylaser Equipment

Dedicated to the research and development, production and sales of laser equipment

More than 10CM marble tabletop, stable and not shaky

Full envelope 100% protection for production safety

Secondary constant current controller More stable welding current

Quasi-continuous laser with more precise modulation to ±2%

Toflylaser 16years

Dedicated to creating energy-efficient laser equipment

Significantly increase your welding efficiency, reduce production costs, and increase your competitiveness in the marketplace.

16 years of experience in the brand industry

◆ Toflylaser has focused on the development, sales and service of laser equipment and automation equipment for 16 years, and has provided products and services for many industries and enterprises

Industry classic welding equipment

◆ Our 2000+ laser workpiece cases, complete sets of equipment and process solutions

◆ Various customized automatic laser equipment, testing equipment, automatic assembly lines, assembly lines, etc.

Strict process, product layers of control

◆ The company attaches importance to technology research and development and has a group of optical, mechanical, electronic and software development talents who have been working in the laser field for more than ten years and have rich experience in advanced laser applications and equipment manufacturing such as green laser, UV laser and picosecond laser.

Improve the quality service system

◆ Free service during the quality assurance period and lifetime technical service for the product.

◆ Dedicated pre-sales, in-sales and after-sales services make your production worry-free!

◆ We insist on providing high quality and reliable products, and provide you with a full range of solutions to your laser problems, improve laser quality and efficiency with our 16 years of industry experience.

Friendly Links +

Wastewater treatment equipment Touch screen inquiry machine Transparent hydraulic test bench Food testing instruments and equipment Constant temperature and humidity air conditioning Industrial vacuum cleaner Aluminum alloy scaffolding LCD splicing screen manufacturers Self-cleaning filter Watches Smart Meters Industrial aluminum profiles Wastewater Treatment

The company's main industries include medical industry, automotive industry, new energy industry, consumer electronics industry, hardware industry.

Follow us

Copyright © 2021 Suzhou Toflylaser Technology Co., Ltd. All Rights Reserved 苏ICP备16066370号-1 Powered by 300.cn