Product Center

Pico-second laser cutter

- Product Description

- Advantages

- Parameter

- Applications

-

Welding Samples

Pull Test

Partner

Product Description

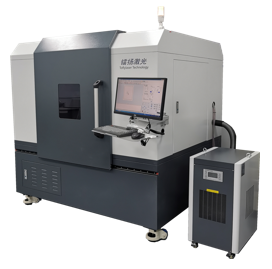

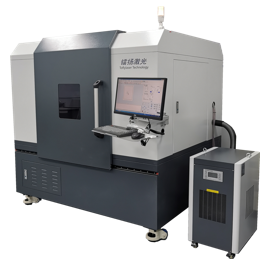

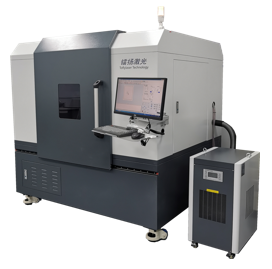

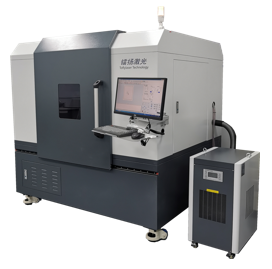

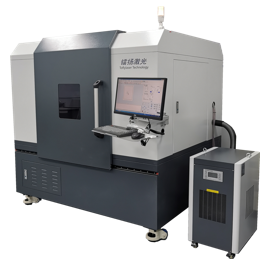

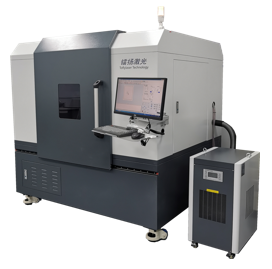

Picosecond Precision Cutting Machine

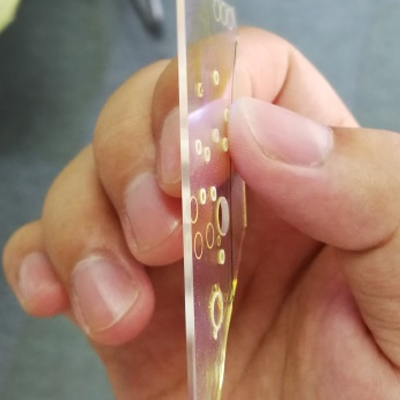

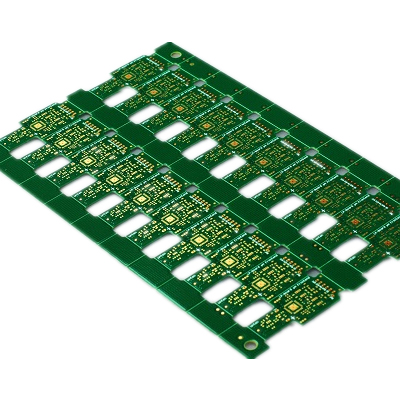

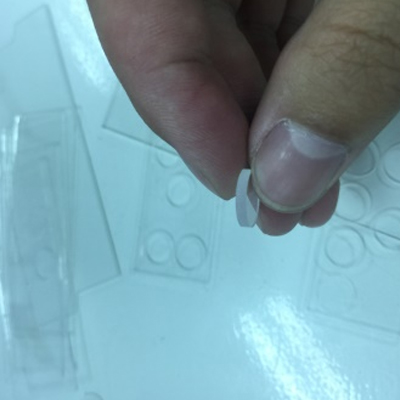

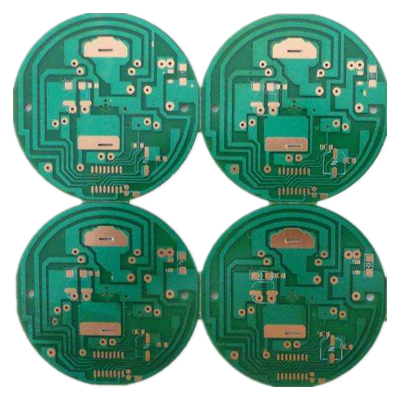

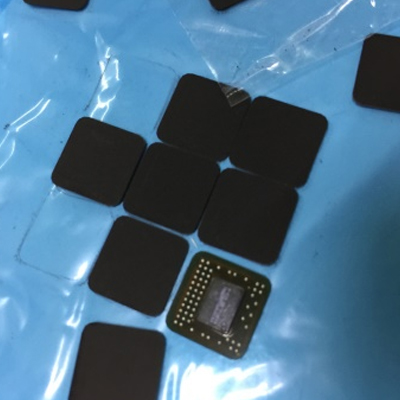

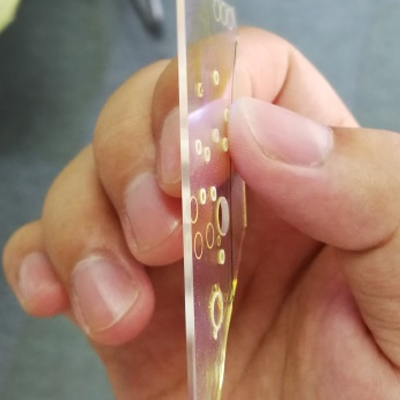

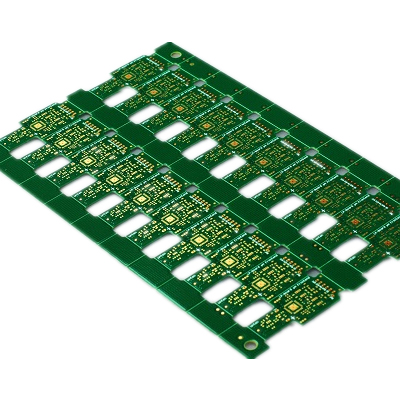

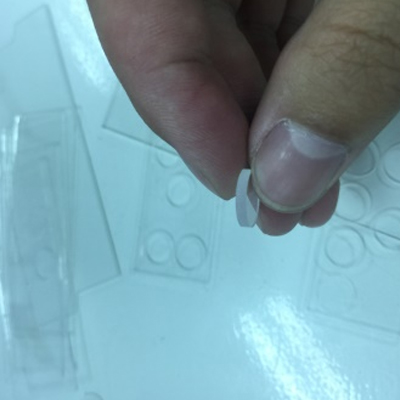

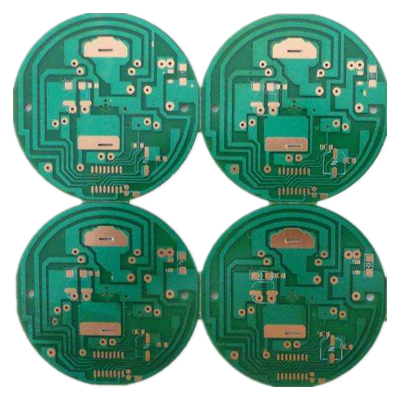

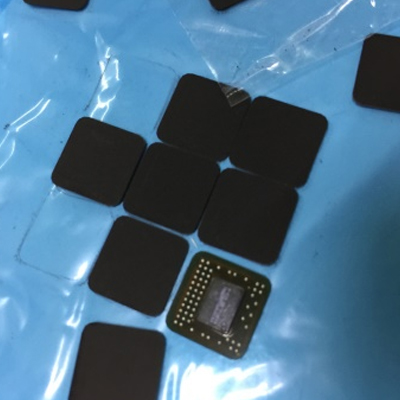

The picosecond laser with ultra-short pulses and almost no heat transfer is suitable for high-speed cutting and drilling of any organic and inorganic materials with a minimum of 3μm chipping and heat affected zone. It can process materials such as silver paste, ITO, Cu, glass, sapphire, ceramics, ultra-thin metal sheets, polymer composite materials, silicon wafers, and various alloy materials and thin film materials.

C10-PF-T

C30-PF-T

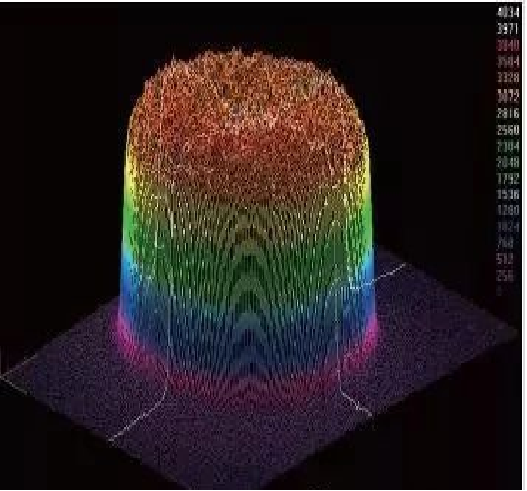

01 Precise ultra-short pulse width, almost no heat transfer to

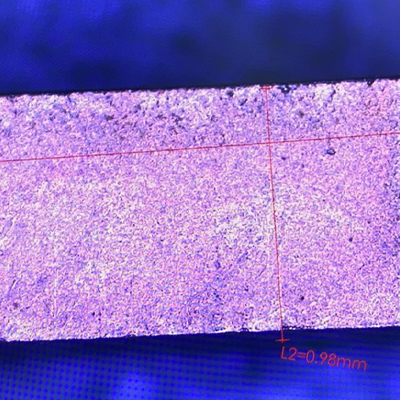

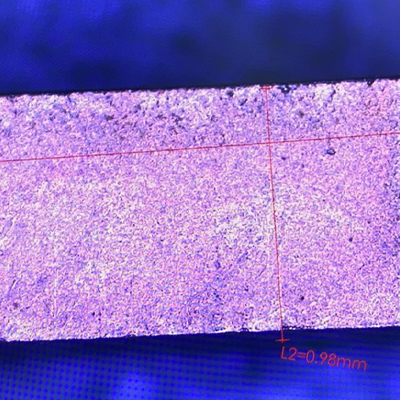

With picosecond laser, ultra-short pulse processing with almost no heat transfer, suitable for high-speed cutting and drilling of any organic and inorganic materials with minimum 3μm chipping and heat-affected zone. It can process materials such as silver paste, ITO, Cu, glass, sapphire, ceramic, ultra-thin metal sheet, polymer composite material, silicon wafer, and various alloy materials and thin film materials, CCD visual pre-scan & automatic target positioning, maximum processing range of 500×400m, XY platform splicing accuracy ≤±3μm, excellent beam quality, good long-term stability.

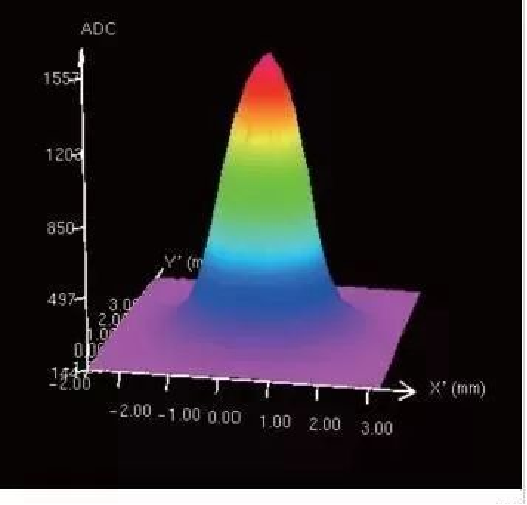

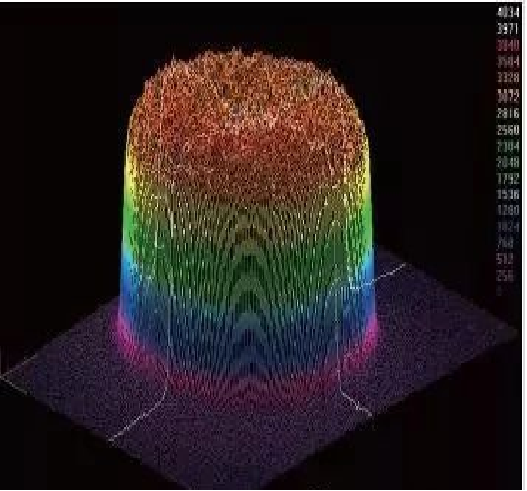

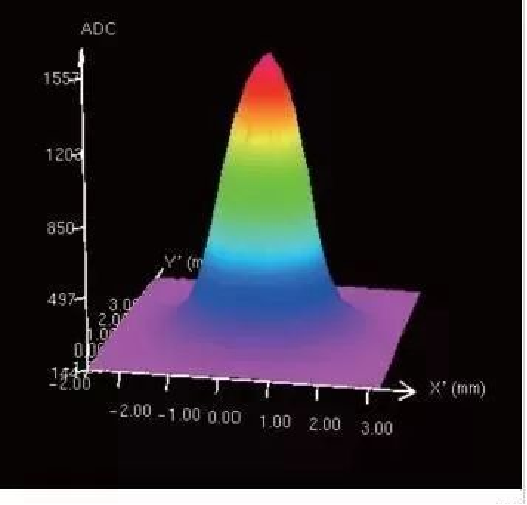

02 High precision oscillator, first choice for precision micro machining

Adopt imported Q switch and high-speed oscillator scanning system, high laser peak power, fast scanning speed, suitable for laser precision marking and micro processing.

03 Intelligent software, humanized operation

Advanced hardware control technology and intelligent software, easy to operate, stable performance, providing customers with efficient and economic mass production processing

04 Easy maintenance and stable performance

Stable machine performance, long life, high electro-optical conversion rate. Low energy consumption, easy maintenance, cost saving, with a variety of laser types and equipment types, convenient for customers to choose different processing methods in different sites

Core Component imported configiguration

Customized Project introduction

TFL Dongfeng 7130 Headset Cutting Project Introduction

01 Customer background and pain points

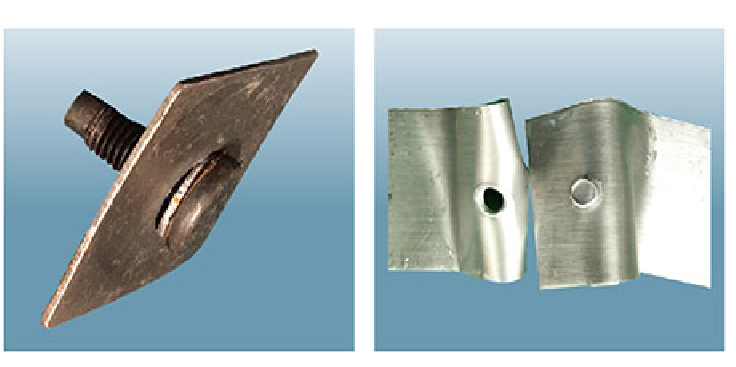

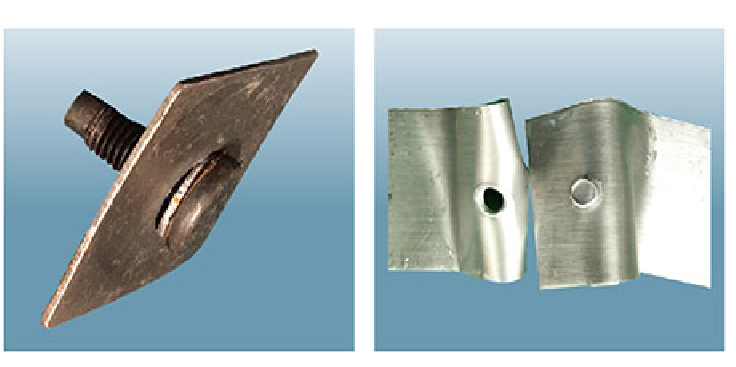

Dongfeng Motor Company, an old central enterprise to produce and manufacture automobiles, the customer needs to cut 0.1mm products from the blank material after stamping, the problems encountered are

1, cutting efficiency is particularly low: the original process, with the traditional laser cutting configuration, low efficiency.

2, the burr length is not up to standard: due to the material 0.1mm stainless steel sheet, the length is relatively long 500mm, resulting in cutting deformation, burr long.

The above two points customers are very distressed, has not been able to find a solution.

02 High customer demand for equipment

DFB found us online on October 16, 2019 and discussed with our sales project engineer and wanted to customize the welder with the following requirements.

1、Improve the efficiency of cutting.

2, reduce the number of fixture repair.

3, cutting efficiency to be increased by 50% on the original basis.

4, the finished product rate to be increased by 30% on the basis of the original.

5, to solve the problem of cutting instability.

According to the requirements proposed by the customer, the existing standard laser cutting machine simply can not achieve, how to do?

03 Customized W150-F-J quasi-continuous laser welding machine developed by customers according to their requirements

According to the customer's requirements, our R&D department, cutting process department and sales department held a new project R&D meeting together, discussing the process, fixture, structure, feeder mode, configuration, listing the key risk points and making solutions one by one, determining the basic direction and technical details as follows.

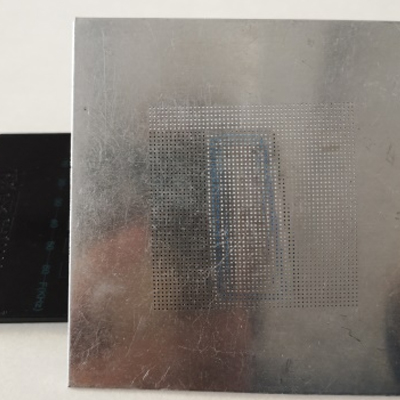

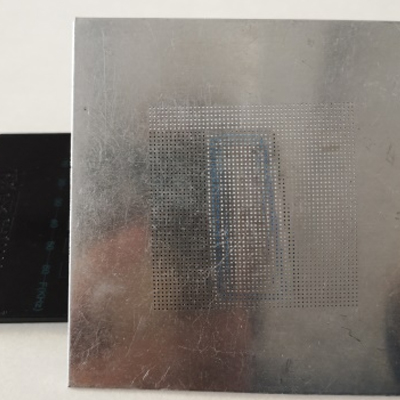

1、Prototype test of workpiece: Laser Yang cutting technician made a simple fixture for prototype as fast as possible and used our existing medium frequency welder for prototype test, after 3 days of back and forth test and good microscope magnification test by both sides, basically determined the cutting parameters.

2, equipment selection: R & D engineers and cutting process engineers to communicate together and according to customer requirements to figure out the selection of power, and finally confirmed as C1000-F-G stainless steel sheet cutting machine.

3, the stability of the equipment: our company uses the core components all "imported configuration".

4, the advantages of the equipment.

(1) we choose the stainless steel sheet automatic cutting machine, using linear motors, more than 50% more efficient than the original servo motor module.

(2) we have chosen a special laser module to solve the burr phenomenon, high yield, stable welded joints, high strength, burr up to 5um or less.

3) Easy to operate, ordinary workers can operate, do not need professional welders, saving labor costs.

4) with automatic displacement tooling, cutting efficiency can be increased by 50% on the original basis.

5)Adopting double vibration lens cutting, the finished product rate is high, which can be increased by 30% on the original basis.

5、Delivery time: 25 working days.

04 Efficient design, timely delivery, professional service, customer consistent praise

After confirming the technical agreement of the equipment and signing the contract, the project manager of Rayon held the production project initiation meeting in the first time, determined the mechanical design, electrical design, mechanical processing, outsourcing parts, assembly, joint tuning time nodes and the customer's pre-acceptance, rectification, general inspection and delivery time to the factory, and arranged and sent work orders of all departments through ERP system, and supervised and followed up the work process of all departments in an orderly manner.

In the blink of an eye, 30 working days have passed, and the customized stainless steel sheet cutting machine of Dongfeng Motor has been completed after aging test. After 2 days and 1 night of installation and commissioning and technical, operation and maintenance training by our professional after-sales engineers at the customer's site, the equipment has been put into production normally and has all reached the customer's acceptance standard. Dongfeng Motor Company is very satisfied with the actual production and cutting effect of the stainless steel sheet cutting machine, helping them to solve the problem of cutting yield, improve the cutting efficiency, save labor, and also give us high recognition and praise!

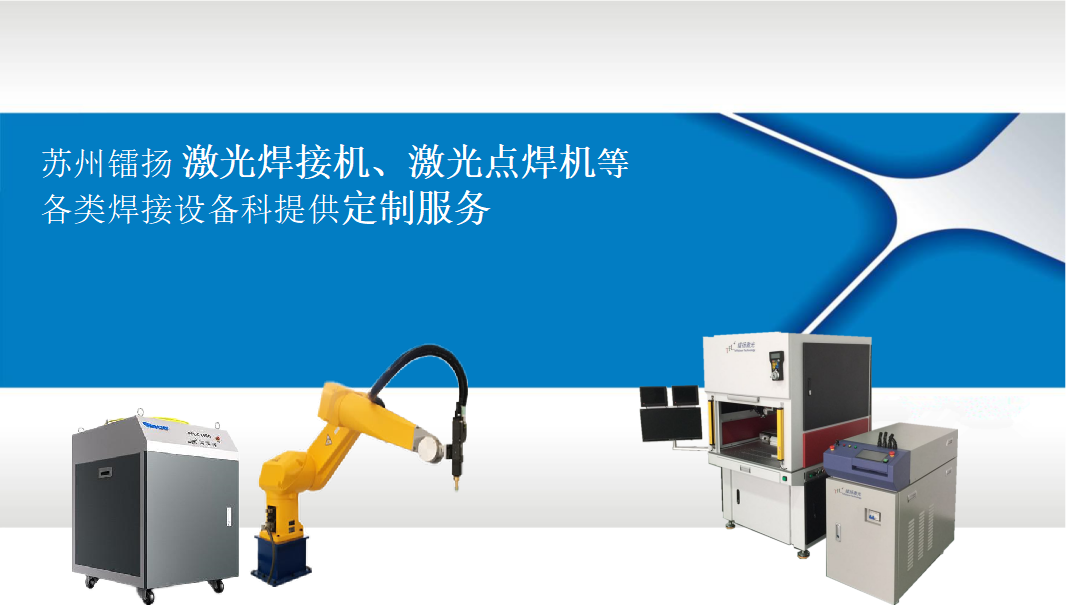

05 Meeting your customized needs is the mission of Rayon's continuous development

Our customer base is our guide.

What material do you need to cut?

What cutting requirements? What cutting process?

Do you need fully automatic, semi-automatic, or assembly line?

Please feel free to ask us any questions, and we can "customize R&D" for you.

Customer cases

Amphenol Headset Laser Welding Line

Battery lug automatic welding machine

Laser Welding Machine for Medical Devices

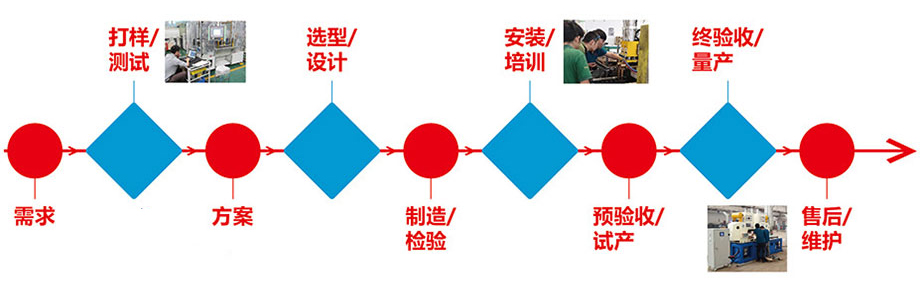

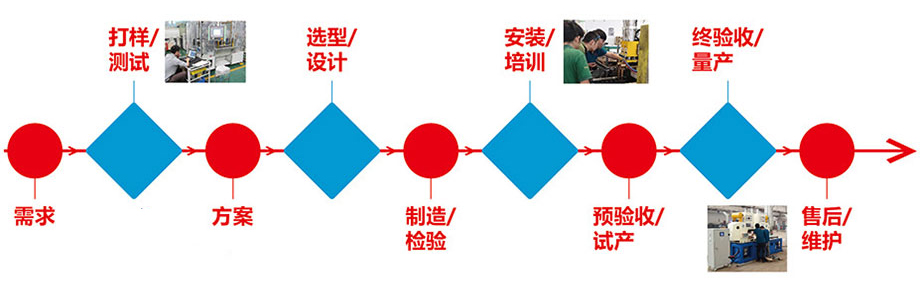

R&D CUSTOM PROCESS

Professional and attentive service, Radiant all the way to accompany!

Service System

Radiant's 20-strong service team, 24h*7 service online, 8h service to home, lifetime maintenance!

After-sales engineers come to the factory for free to install and debug, hand-hold training, to escort you!

GROUPED EQUIPMENT

Pressure Detector

Laser Power Meter

-

1、配备安全防护罩,避免设备操作员 误操作引起的人身伤害

2、采用进口Q开关和高速振镜扫描系统,激光峰值功率高,扫描速度快,适合激光精密打标和微加工

3、先进的硬件控制技术和智能化软件,操作简便,性能 稳定,为客户提供高效经济的量产加工

4、机器性能稳定,寿命长,电光转换率高。低能耗、易维护、节约成本,具备多种激光器类型和设备类型,方便客户在不同场地选择不同的加工方式 -

型号 Model

C10-PF-T

C30-PF-T

C50-PF-T

最大平均功率 Average Power

1064nm

10W

30W

50W

532nm

4W

12W

25W

355nm

3W

9W

15W

单脉冲能量 Wavelength

1064nm

70uJ

250uJ

200uJ

532nm

40uJ

60uJ

125uJ

355nm

20uJ

45uJ

75uJ

脉冲宽度 pulse width

<13ps@1064nm, <10ps@532nm, <8.5ps@355nm

激光频率 Frequency

100-600KHz

最小线宽 Minimum line width

0.02mm

0.03mm

0.03mm

重复定位精度 Repeated accuracy

±2μm

±2μm

±2μm

冷却方式 Cooling

水冷

电力系统 Power Supply

800W(二相)

1500W(二相)

2200W(二相)

供电要求 Voltage Supply

220V±10%

-

医疗器械、消费电子行业、传感器件、航空航天,新能源锂电、燃料电池等精密产品五金工具制品、精密器械