Product Center

Handheld laser cleaning machine

- Product Description

- Advantages

- Parameter

- Applications

-

Cleaning Samples

Partner

Product Description

W150-QCW-G Quasi-Continuous Laser Cleaner

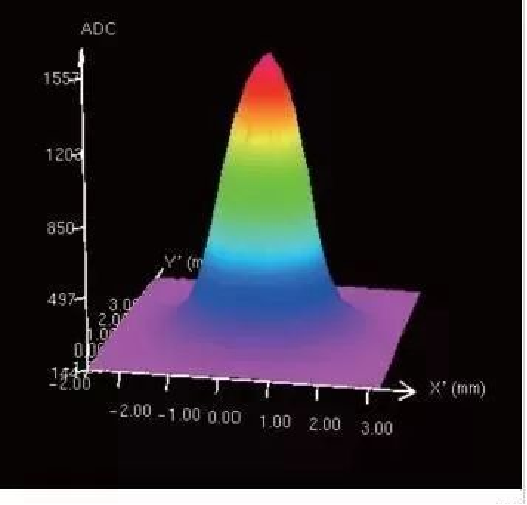

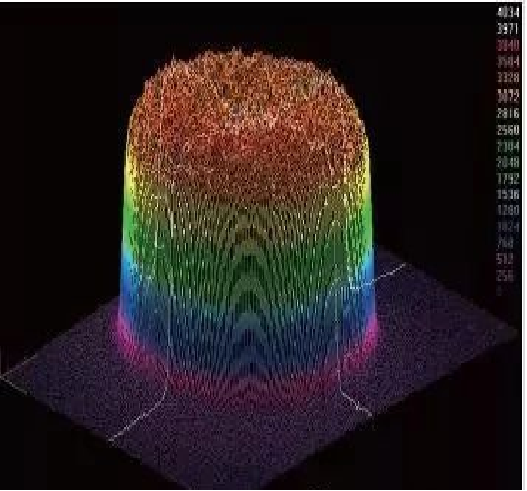

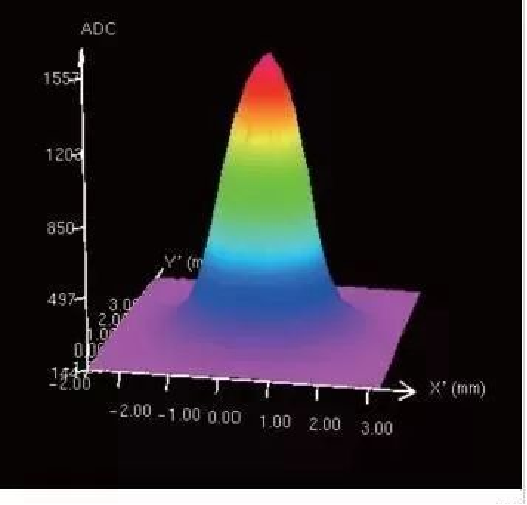

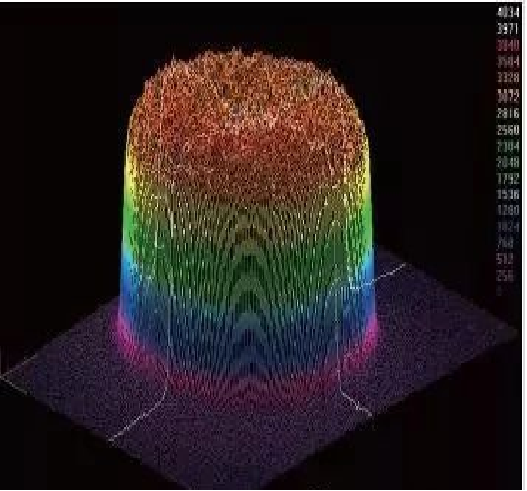

QCW is a quasi-continuous fiber laser, with pulse control to control the continuous fiber laser, to obtain the higher peak power and laser energy that the pulsed laser has, but also has the excellent beam quality of the fiber laser, to achieve the best cleaning effect. It is one of the current advanced cleaning methods

C100-F-J

C200-F-J

01 Lightweight cleaning head

Lightweight laser cleaning head weighs only 620g (without armor cable) for extended handheld operation

02 Wireless tuning parameters

Wireless control, can realize the parameter adjustment and light control from a distance

03 Portable trolley easy to check in

Portable trolley case design, the whole weight of 28kg, can take high-speed rail or airline check-in

04 Adapted to different field mirrors

Red light assisted focus seeking, and can be adjusted according to different field mirror focus position

Core Component imported configiguration

Customized Project introduction

TFL Hankawa Smart 7130 Headset Welding Project Introduction

01 Customer background and pain points

HANCHUAN Intelligent Company, mainly engaged in new energy non-standard automatic production equipment. The end customer of HANCHUAN Intelligent needs to laser clean off the toner on the surface of 0.01mm thickness of thin purple copper sheet, which cannot be perforated or residual toner, and the problems encountered are

1, cleaning efficiency is particularly low: the original process material surface can only withstand 60 watts of laser power, low efficiency.

2, easy to perforation is not up to standard: because the material is very thin purple copper sheet, some differences in parameters will easily lead to copper sheet perforation

The above two points customers are very distressed, has not been able to find a solution.Translated with www.DeepL.com/Translator (free version)

02 High customer demand for equipment

Hanchuan Intelligence found us online on July 19, 2020, and our sales project engineer discussed and wanted to customize the laser cleaning machine with the following requirements.

1、Improve the efficiency of cleaning.

2, cleaning efficiency required to improve 35% on the original basis.

4, the finished product rate should be increased by 25% on the basis of the original.

5, to solve the problem of cleaning instability.

According to the requirements of the customer, the existing standard point convex laser cleaning machine simply can not be achieved, how to do?

03 Customized W150-F-J quasi-continuous laser welding machine developed by customers according to their requirements

According to the customer's requirements, the company's R & D department, cleaning process department, sales department held a new project R & D meeting, together to discuss the process, fixture, structure, feed mode, configuration, list the key risk points, and make a solution one by one, to determine the basic direction and technical details as follows.

1, workpiece proofing test: Laser Yang cleaning technician to the fastest speed to do the proofing of the simple fixture, with our existing medium frequency laser cleaning machine proofing test, after 5 days of back and forth testing and good pull test, basically determine the good cleaning parameters.

2, equipment selection: R & D engineers and cleaning process engineers to communicate together and according to customer requirements to figure out the selection of power, and finally confirmed as C200-F-S laser cleaning machine.

3, the stability of the equipment: our company uses the core components all "imported configuration".

4, the advantages of the equipment.

(1) we choose the double-headed automatic point laser cleaning machine, than the original single-point efficiency increased by more than 50%.

(2) we have chosen a special laser structure, to solve the phenomenon of perforation, high yield, stable welding joints, high strength.

3) Easy to operate, ordinary workers can operate, do not need professional welders, saving labor costs.

4) with automatic displacement tooling, cleaning efficiency can be increased by 50% on the basis of the original.

5)With double vibration lens cleaning, the finished product rate is high, which can be increased by 30% on the original basis.

5、Delivery time: 20 working days.

04 Efficient design, timely delivery, professional service, customer consistent praise

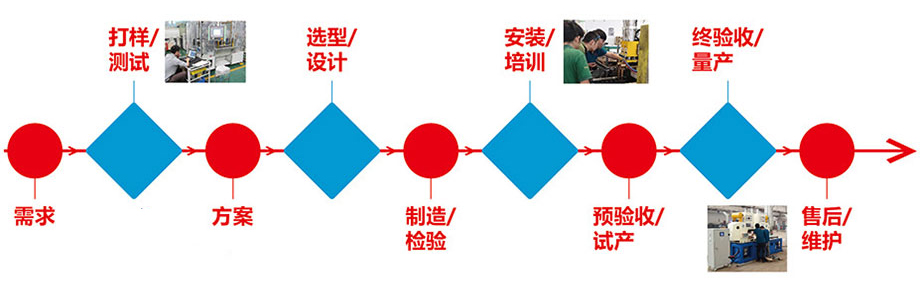

After confirming the technical agreement of the equipment and signing the contract, the project manager of Radiant Young held the production project initiation meeting at the first time, determined the mechanical design, electrical design, mechanical processing, outsourcing parts, assembly, joint tuning time nodes and the customer's pre-acceptance, rectification, general inspection and delivery time to the factory, and arranged and sent out the work orders of each department through ERP system in an orderly way, and supervised and followed up the work process of each department.

Soon after 35 working days passed, HANCHUAN's customized double-head laser cleaning machine was completed after aging test. After 1 day and 1 night of installation and commissioning and technical, operation and maintenance training by our professional after-sales engineers at the customer's site, the equipment was put into production normally and all of them reached the customer's acceptance standard. Hanchuan Intelligent Company is very satisfied with the actual production and cleaning effect of the double-head laser cleaning machine, helping them to solve the problem of cleaning yield, improve the cleaning efficiency, save labor, and also give us high recognition and praise!

05 Meeting your customized needs is the mission of Rayon's continuous development

Our customer base is our guide.

What material do you need to clean?

What cleaning requirements? What cleaning process?

Do you need a fully automatic, semi-automatic, or in-line machine?

Please feel free to ask us any questions, and we can "customize the development" for you.

Customer cases

Amphenol Headset Laser Welding Line

Battery lug automatic welding machine

Laser Welding Machine for Medical Devices

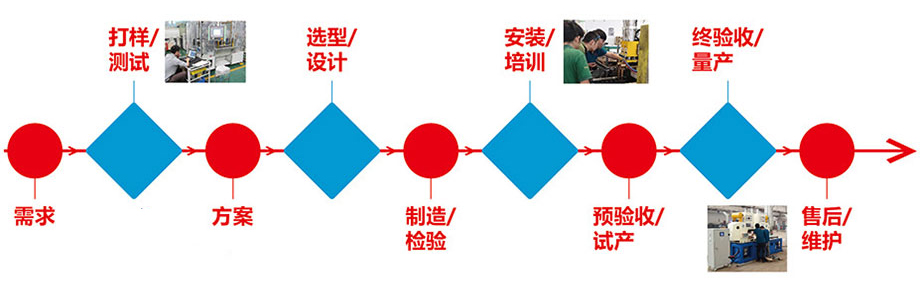

R&D CUSTOM PROCESS

Professional and attentive service, Radiant all the way to accompany!

Service System

Radiant's 20-strong service team,24h*7service online, 8h service to home, lifetime maintenance!

After-sales engineers come to the factory for free to install and debug, hand-hold training, to escort you!

GROUPED EQUIPMENT

Pressure Detector

Laser Power Meter

Tensiometer

-

1、Lightweight and compact output armor cable end

2、Collimated output, collimated spot size can be customized

3、Lightweight laser cleaning head, weighing only 620g (without armor cable), can be handheld for a long time

4、Red light assisted focusing, and can be adjusted according to different field mirror focusing position

5、Wireless control, can be a long distance to achieve parameter adjustment and light control

6, portable trolley case design, the whole weight of 28kg, can take the high speed rail or airline check-in

7, high strength injection molding case, stable structure, wear-resistant, shockproof, anti-drop -

Model

C100-F-J

C120-F-J

C200-F-J

C350-F-J

Average Power

100W

120W

120W

350W

Wavelength

1064nm

Laser Model

Fiber

Frequency

1-2000KHz

1-2000KHz

1-2000KHz

1-2000KHz

Pulse width

3-400ns

3-400ns

3-400ns

3-400ns

Repeated accuracy

±2μm

±2μm

±2μm

±2μm

Cooling

Air-cooled Power Supply

500W(Two-phase)

500W(Two-phase)

1000W(Two-phase)

1500W(Two-phase)

Voltage Supply

220V±10%

-

Sheet metal, rail transportation, ship, new energy, lithium