Product Center

Fiber Optic Precision Cutting Machine

- Product Description

- Advantages

- Parameter

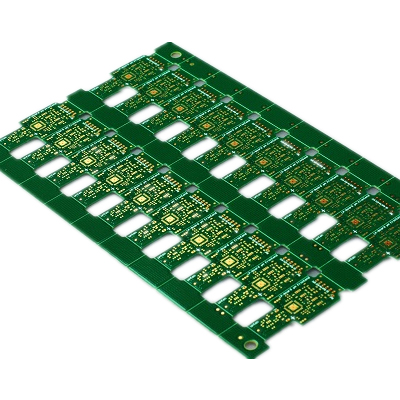

- Applications

-

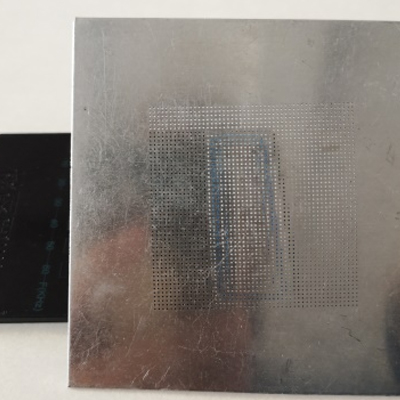

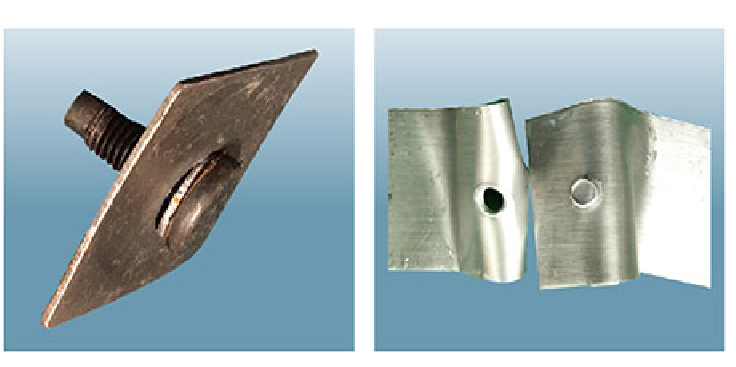

Welding Samples

Pull Test

Partner

Product Description

Fiber Optic Precision Cutting Machine

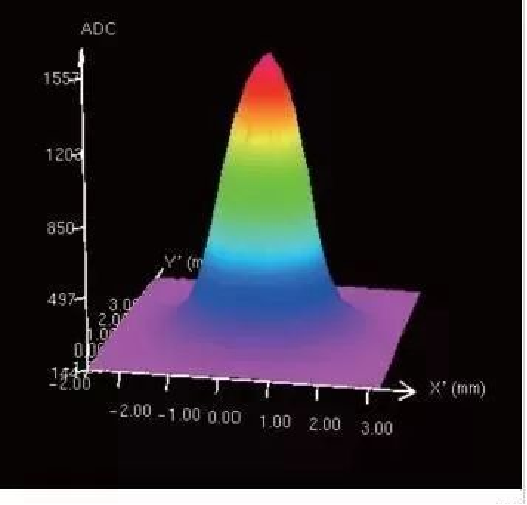

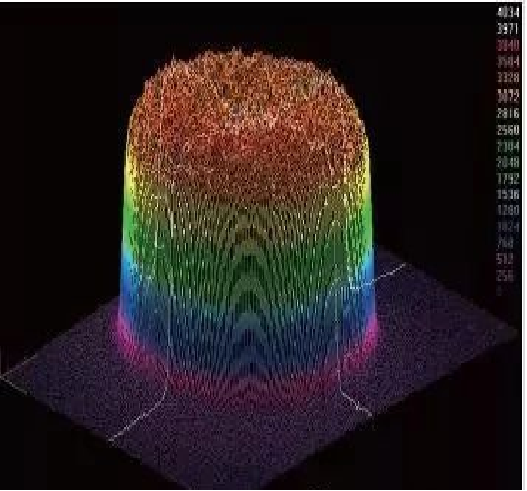

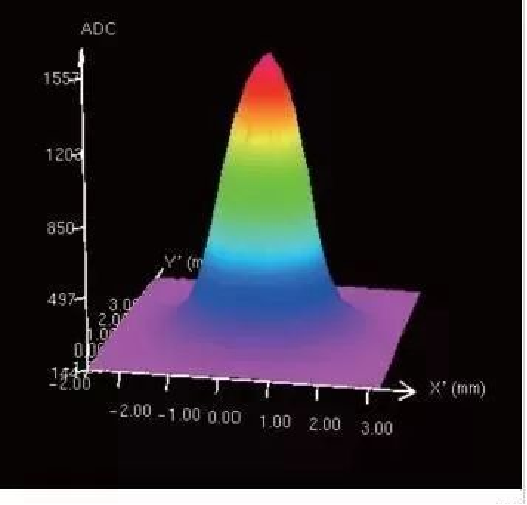

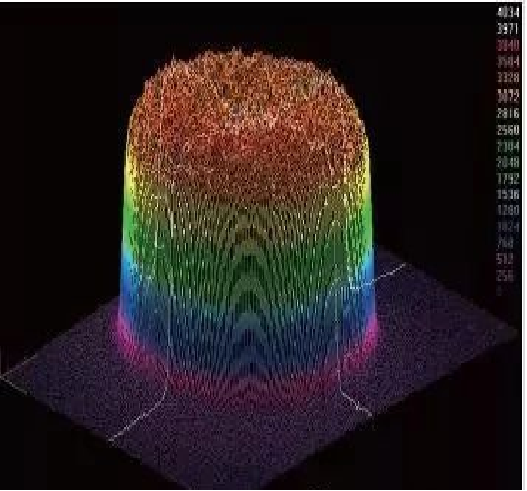

Fiber laser, wavelength 1064ns, good beam quality, high power density, very conducive to the absorption of metal materials, has excellent cutting ability. The laser beam is focused into a very small spot, so that the focal point to achieve a high power density, the material is quickly heated to the degree of vaporization, the kerf width is generally 0.05-0.20mm, positioning accuracy 0.05mm, repeat positioning accuracy 0.03mm, cutting speed up to 10m / min. high conversion efficiency, conversion efficiency of 30% or more, can significantly Save the power consumption when working.

Translated with www.DeepL.com/Translator (free version)

C1000-F-L

C1500-F-L

01 Precise ultra-short pulse width, almost no heat transfer to

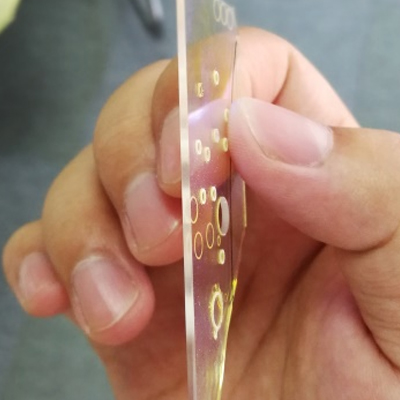

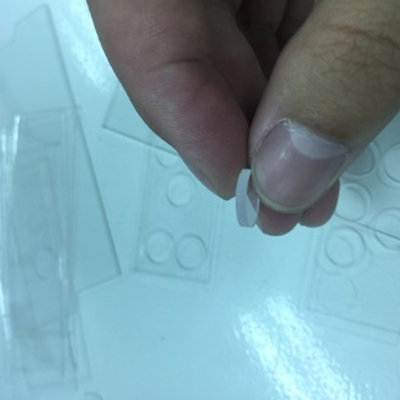

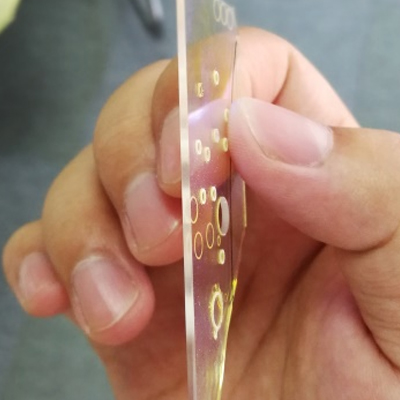

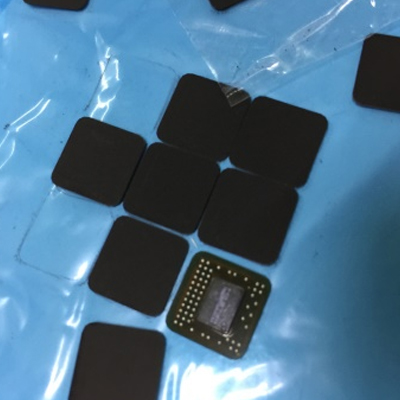

With picosecond laser, ultra-short pulse processing with almost no heat transfer, suitable for high-speed cutting and drilling of any organic and inorganic materials with minimum 3μm chipping and heat-affected zone. It can process materials such as silver paste, ITO, Cu, glass, sapphire, ceramic, ultra-thin metal sheet, polymer composite material, silicon wafer, and various alloy materials and thin film materials, CCD visual pre-scan & automatic target positioning, maximum processing range of 500×400m, XY platform splicing accuracy ≤±3μm, excellent beam quality and long-term working stability.

02 High-precision vibrating mirror, preferred for precision micromachining

Adopt imported Q switch and high-speed oscillator scanning system, high laser peak power, fast scanning speed, suitable for laser precision marking and micro processing.

03 Intelligent software, humanized operation

Advanced hardware control technology and intelligent software, easy to operate, stable performance, providing customers with efficient and economic mass production processing

04 Easy maintenance and stable performance

Stable machine performance, long life, high electro-optical conversion rate. Low energy consumption, easy maintenance, cost saving, with a variety of laser types and equipment types, convenient for customers to choose different processing methods in different sites

Core Component imported configiguration

Customized Project introduction

TFLamphenol 7130 headphone soldering project introduction

01 Customer background and pain points

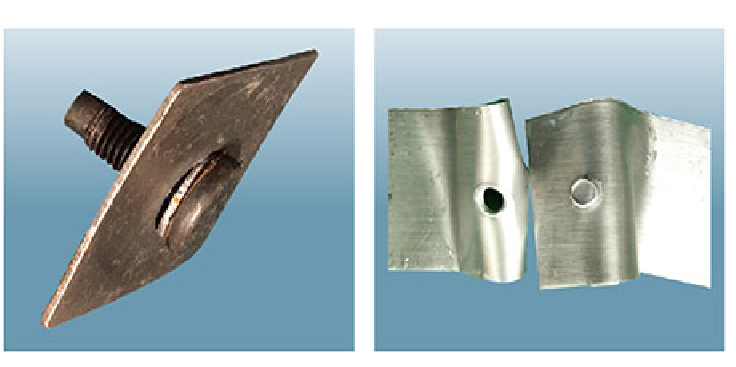

Dongfeng Motor Company, an old central enterprise to produce and manufacture automobiles, the customer needs to cut 0.1mm products from the blank material after stamping, the problems encountered are

1, cutting efficiency is particularly low: the original process, with the traditional laser cutting configuration, low efficiency.

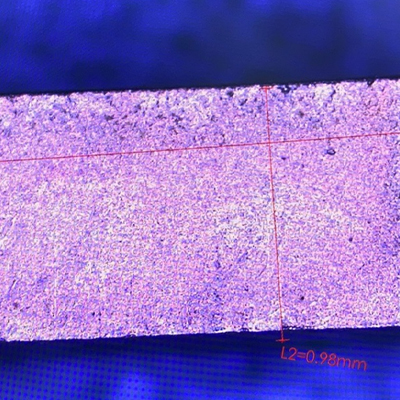

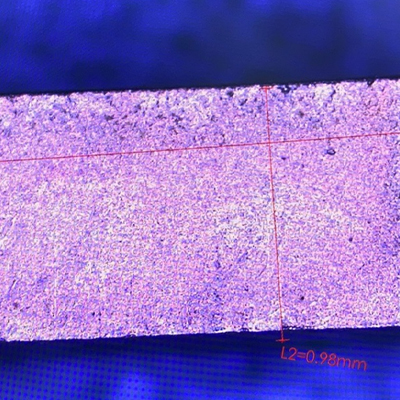

2, the burr length is not up to standard: due to the material 0.1mm stainless steel sheet, the length is relatively long 500mm, resulting in cutting deformation, burr long.

The above two points customers are very distressed, has not been able to find a solution.02 High customer demand for equipment

DFB found us online on October 16, 2019 and discussed with our sales project engineer and wanted to customize the welder with the following requirements.

1、Increasing the efficiency of cutting.

2. reducing the number of fixture repairs.

3, cutting efficiency to be increased by 50% on the original basis.

4, the finished product rate to be increased by 30% on the basis of the original.

5, to solve the problem of cutting instability.

According to the requirements proposed by the customer, the existing standard laser cutting machine simply can not achieve, how to do?

03 Customized W150-F-J quasi-continuous laser welding machine developed by customers according to their requirements

According to the customer's requirements, our R&D department, cutting process department and sales department held a new project R&D meeting together, discussing the process, fixture, structure, feeder mode, configuration, listing the key risk points and making solutions one by one, determining the basic direction and technical details as follows.

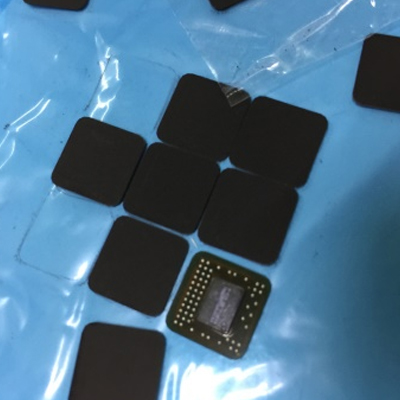

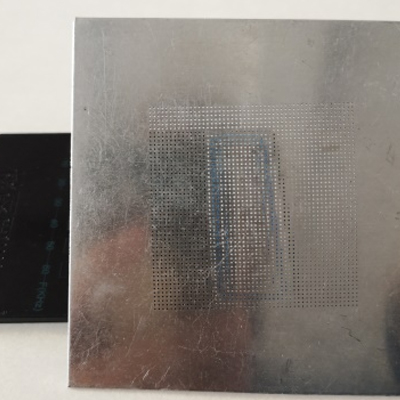

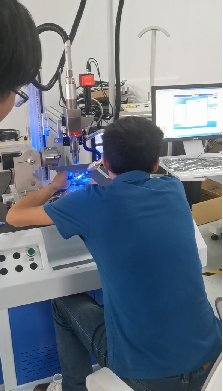

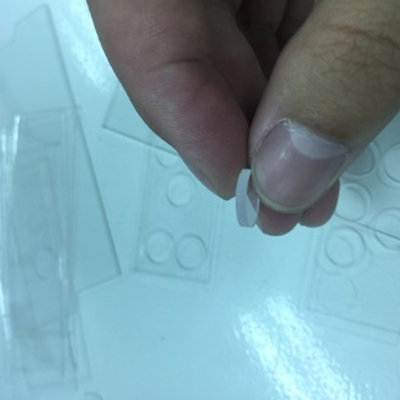

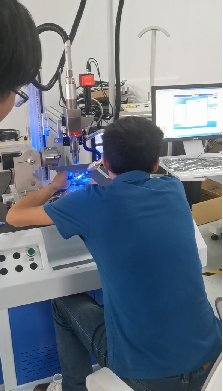

1、Prototype test of workpiece: Laser Yang cutting technician made a simple fixture for prototype as fast as possible and used our existing medium frequency welder for prototype test, after 3 days of back and forth test and good microscope magnification test by both sides, basically determined the cutting parameters.

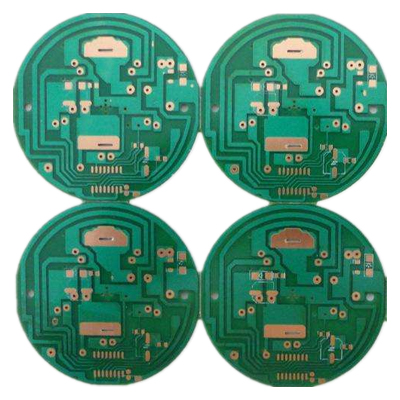

2, equipment selection: R & D engineers and cutting process engineers to communicate together and according to customer requirements to figure out the selection of power, and finally confirmed as C1000-F-G stainless steel sheet cutting machine.

3, the stability of the equipment: our company uses the core components all "imported configuration".

4, the advantages of the equipment.

(1) we choose the stainless steel sheet automatic cutting machine, using linear motors, more than 50% more efficient than the original servo motor module.

(2) we have chosen a special laser module to solve the burr phenomenon, high yield, stable welded joints, high strength, burr up to 5um or less.

3) Easy to operate, ordinary workers can operate, do not need professional welders, saving labor costs.

4) with automatic displacement tooling, cutting efficiency can be increased by 50% on the original basis.

5)Adopting double vibration lens cutting, the finished product rate is high, which can be increased by 30% on the original basis.

5、Delivery time: 25 working days.

04 Efficient design, timely delivery, professional service, customer consistent praise

After confirming the technical agreement of the equipment and signing the contract, the project manager of Rayon held the production project initiation meeting in the first time, determined the mechanical design, electrical design, mechanical processing, outsourcing parts, assembly, joint tuning time nodes and the customer's pre-acceptance, rectification, general inspection and delivery time to the factory, and arranged and sent work orders of all departments through ERP system, and supervised and followed up the work process of all departments in an orderly manner.

In the blink of an eye, 30 working days have passed, and the customized stainless steel sheet cutting machine of Dongfeng Motor has been completed after aging test. After 2 days and 1 night of installation and commissioning and technical, operation and maintenance training by our professional after-sales engineers at the customer's site, the equipment has been put into production normally and has all reached the customer's acceptance standard. Dongfeng Motor Company is very satisfied with the actual production and cutting effect of the stainless steel sheet cutting machine, helping them to solve the problem of cutting yield, improve cutting efficiency, save labor, and also give us high recognition and praise!

05 Meeting your customized needs is the mission of Rayon's continuous development

Our customer base is our guide.

What material do you need to cut?

What cutting requirements? What cutting process?

Do you need fully automatic, semi-automatic, or assembly line?

Please feel free to ask us any questions, and we can "customize R&D" for you.

Customer cases

Amphenol Headset Laser Welding Line

Battery lug automatic welding machine

Laser Welding Machine for Medical Devices

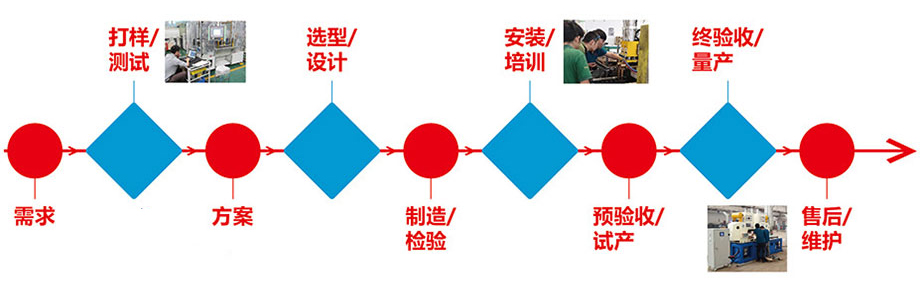

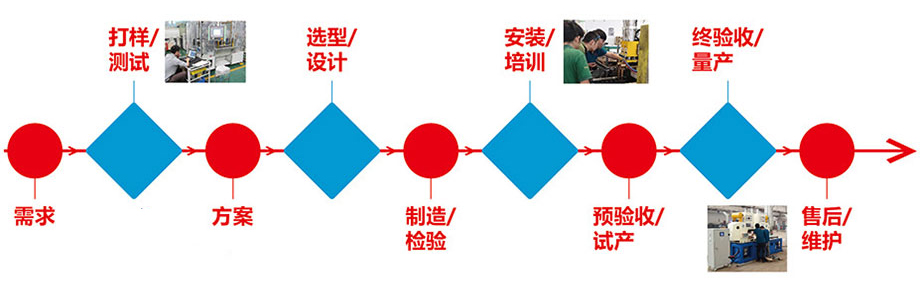

R&D CUSTOM PROCESS

Professional and attentive service, Radiant all the way to accompany!

Service System

Radiant's20-strong service team,24h*7service online, 8h service to home, lifetime maintenance!

After-sales engineers come to the factory for free to install and debug, hand-hold training, to escort you!

GROUPED EQUIPMENT

Pressure Detector

Laser Power Meter

Tensiometer

-

Higher production efficiency, excellent dust and smoke removal structure, higher safety factor.

The machine adopts the overall profile welding structure which has been proved and verified by CAE analysis for many times. Finishing after annealing to eliminate the internal stress, which better solves the stress caused by welding and processing, thus improving the rigidity and stability of the machine.

The gantry adopts high-strength aluminum alloy integral casting structure, which has the advantages of light quality and good dynamic response.

X/Y axis adopts precision helical gear transmission mechanism, which effectively ensures the accuracy and speed in the cutting process.

Imported laser, better stability and longer service life.

Adopting Hans102 digital control system independently developed by Radiant, with friendly interface, easy operation and real-time feedback on processing status, which ensures the orderly processing. -

Model

C500-F-L

C1000-F-L

C1500-F-L

C2000-F-Q

C3000-F-Q

Average Power

100W

200W

300W

500W

1000W

Wavelength

1064nm

Laser Model

Fiber

Frequency

20-2000KHz

2-2000KHz

30-2000KHz

CW laser

Pulse width

30-1500ns

30-1500ns

30-240ns

/

Repeated accuracy

±2μm

±2μm

±2μm

±2μm

±2μm

Cooling

Water cooling Power Supply

1500W(Two-phase)

3000W(three phases)

5000W(three phases)

7000W(three phases)

10000W(three phases)

Voltage Supply

220V±10%

-

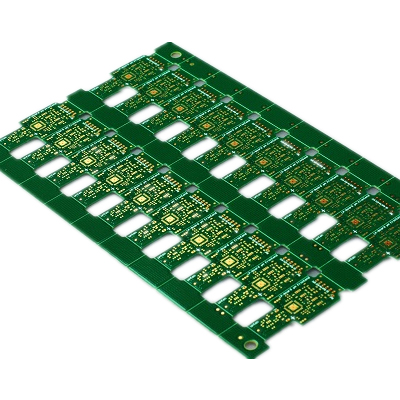

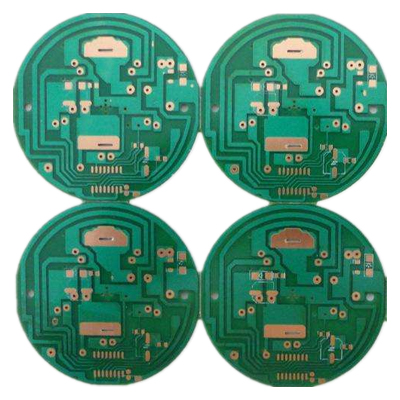

Medical devices, consumer electronics industry, sensor parts, aerospace, new energy lithium, fuel cells and other precision products, automotive industry, precision instruments, gift accessories, high and low voltage electrical appliances.