Product Center

CO2 laser marker

- Product Description

- Advantages

- Parameter

- Applications

-

Welding Samples

Pull Test

Partner

Product Description

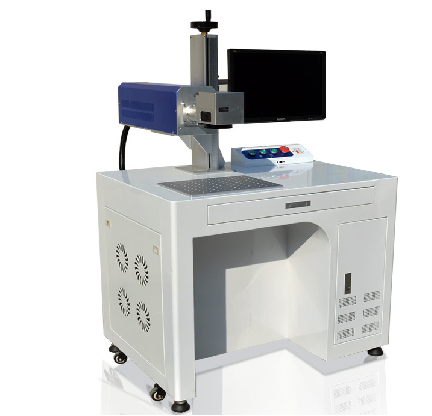

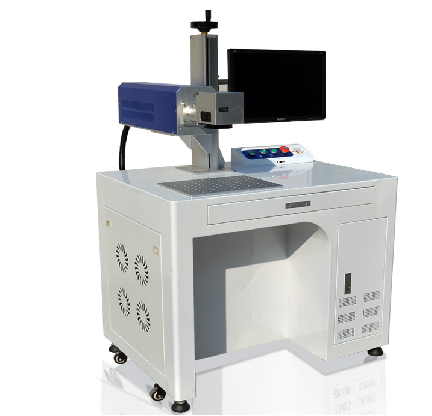

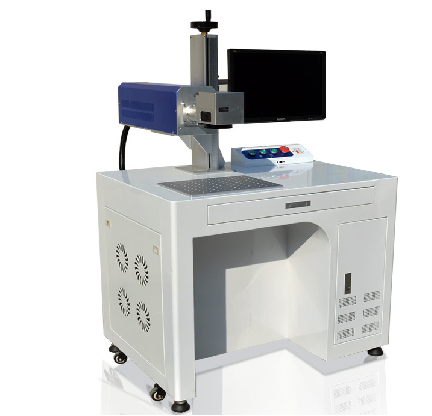

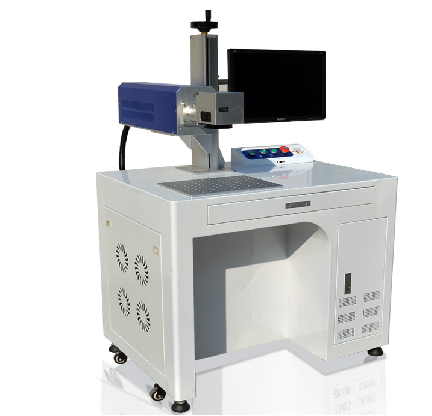

CO2 Laser Marking Machine

CO2 laser is a gas laser, which produces a wavelength of 10.6μm and belongs to the mid-infrared band. CO2 laser has a relatively high power and relatively high electro-optical conversion efficiency. At present, it is mainly used for engraving non-metal and some metal materials.

M30-CO2-D

M50-CO2-D

01 High precision positioning sweep type oscillator

Scanning oscillator system, scanning laser oscillator is the core component of the marking machine, the performance of the marking machine mainly depends on the performance of the scanning laser oscillator, but also through this system to achieve the marking function.

02 Efficient air-cooled cooling

Laser marking machine cooling mode, cooling system is the entire laser machine can be stable and continuous marking premise, heat not only affects the laser out of escape, but also affect the circuit system, fiber laser marking machine through the air-cooled device to reduce the internal temperature of the body, while reducing machine failure, improve equipment stability, and has a small size and fast heat dissipation characteristics.

03 Up to 30% electro-optical conversion efficiency, economic and environmental protection

Fiber lasers, fiber lasers have a more efficient design and use a telecom-grade single-core junction pump source. Fiber lasers do not require adjustment of optics and are maintenance-free or low-maintenance. Fiber lasers are compact and smaller, making them easy to integrate into systems.

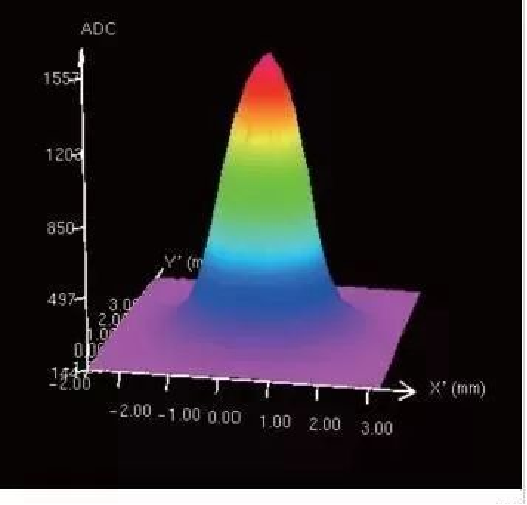

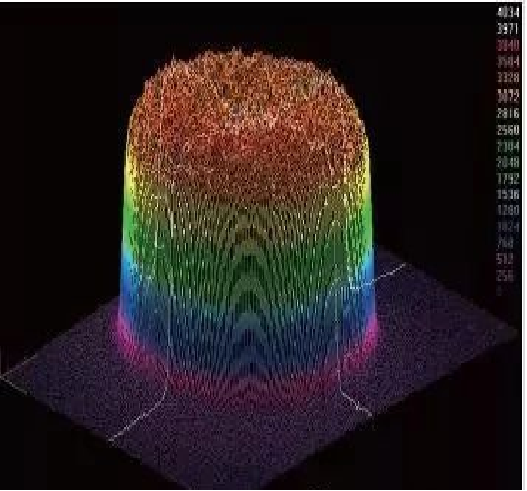

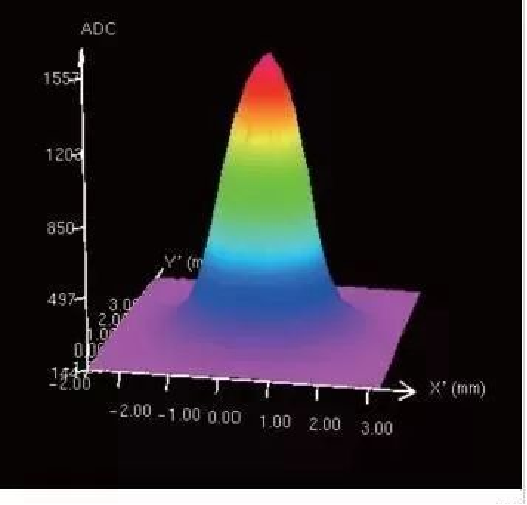

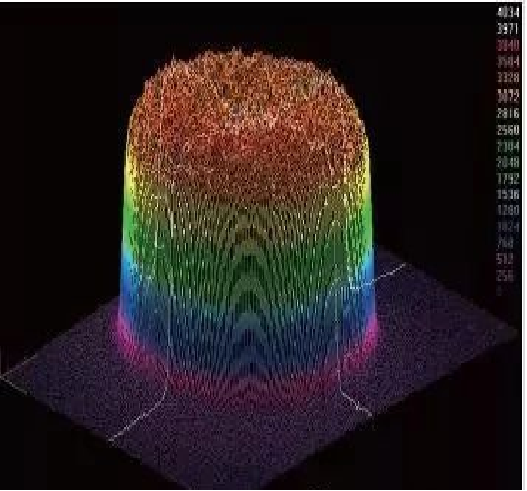

04 Flexibility of beam waveform

Fiber lasers are available with either single-mode or multi-mode output options. For cutting very thin materials or applications requiring a small spot size, single mode would be the appropriate choice. However, most high-power applications will use flat-top light or multimode modes (see illustration).

Core Component imported configiguration

Customized Project introduction

Huichuan Technologies 530 Product Marking Project Introduction

01 Customer background and pain points

Listed company huichuan technology company, is earlier engaged in electromechanical products enterprise, with the gradual popularization of new energy vehicles, more and more fuel engines are replaced by high-power motors, become a new generation of "engine", customers need to hit the engine number on the rough engine surface encountered the following problems: 1, efficiency is particularly low: one mold, one machine efficiency is low.

1, the efficiency is particularly low: a model of a machine efficiency is low.

2, marking depth is not up to standard: because the material is aluminum alloy, size and too large, resulting in insufficient depth.

The above two points customers are very distressed, has not been able to find a solution.

02 High customer demand for equipment

Huichuan Technology approached us online on June 16, 2021 to discuss with our sales project engineer and wanted to customize the welder with the following requirements.

1、Improve the efficiency of marking.

2、Improve the utilization rate of the marking machine.

3, marking efficiency requirements on the basis of the original increase of more than 30%.

4, the finished product rate should be increased by 20% on the original basis.

5、Solve the marking instability problem.

According to the customer's requirements, the existing standard marking machine simply can not achieve, how to do?

03 Customized W150-F-J quasi-continuous laser welding machine developed by customers according to their requirements

According to the customer's requirements, our R&D department, welding process department and sales department held a new project R&D meeting together to discuss the process, fixture, structure, feeder mode, configuration, list the key risk points, and make solutions one by one to determine the basic direction and technical details as follows.

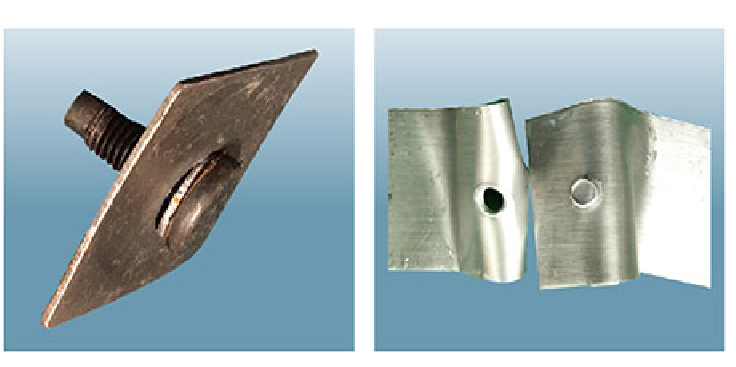

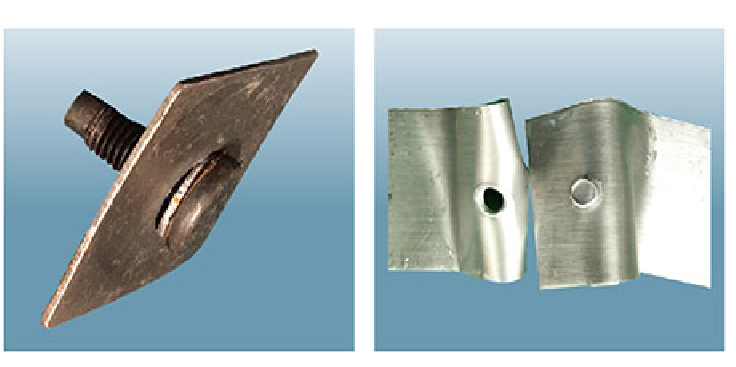

1, workpiece proofing test: Laser Young marking machine technician to do the fastest speed to sample the simple fixture, using our existing laser marking machine proofing test, after 5 days of back and forth testing and good pull test on both sides, basically determine the good welding parameters.

2, equipment selection: R & D engineers and welding processors together to communicate and according to customer requirements to calculate the selection of power, and finally confirmed as M50-F-J2 double-headed laser marking machine.

3, the stability of the equipment: our company uses the core components all "imported configuration";.

4, the advantages of the equipment.

(1) we choose the double-headed laser marking machine, a type can be placed on two engines, the left station marking, the right station on the material, the right station marking, the left station and can be on the material, than the original single-headed efficiency increased by more than 45%.

2) We have chosen a special light source to solve the problem of insufficient marking depth, high yield, stable marking and good depth, which can reach more than 1mm.

3) Easy to operate, ordinary workers can operate, do not need professional welders, saving labor costs.

(4) with the automatic switching function of vibration lens, marking efficiency can be increased by 45% on the original basis.

5)With the double vibrating lens marking machine, the finished product rate is high and can be increased by 20% on the original basis.

5、Delivery time: 25 working days.

04 Efficient design, timely delivery, professional service, customer consistent praise

After confirming the technical agreement of the equipment and signing the contract, the project manager of Rayon held the production project initiation meeting in the first time, determined the mechanical design, electrical design, mechanical processing, outsourcing parts, assembly, joint tuning time nodes and customer's pre-acceptance, rectification, general inspection and delivery time to the factory, and orderly scheduled and sent work orders of all departments through ERP system, and supervised and followed up the work process of all departments.

Soon 35 working days passed, the custom-made Huichuan Technology 7130 headset double-head spot welder was completed after aging test, and after 1 day and 1 night of installation and commissioning and technical, operation and maintenance training by our professional after-sales engineers at the customer's site, the equipment was put into production normally and all reached the customer's acceptance standard. The company is very satisfied with the actual production and marking effect of the dual-head laser marking machine, which helped them solve the problem of marking yield, improve the marking efficiency and save labor, and also gave us high recognition and praise!

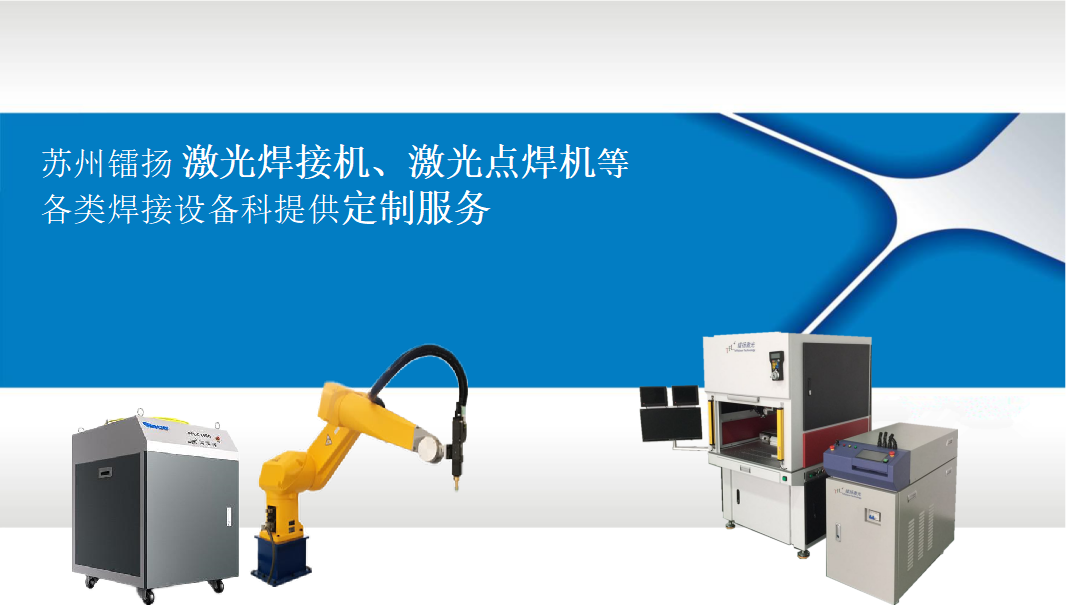

05 Meeting your customized needs is the mission of Rayon's continuous development

Our customer base is our guide.

What material do you need to weld?

What welding requirements? What welding process?

Do you need fully automatic, semi-automatic, or assembly line?

Please feel free to ask us any questions, and we can "customize R&D" for you.

Customer cases

Amphenol Headset Laser Welding Line

Battery lug automatic welding machine

Laser Welding Machine for Medical Devices

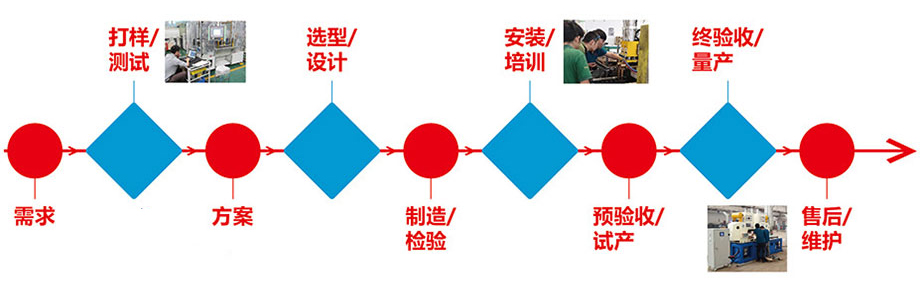

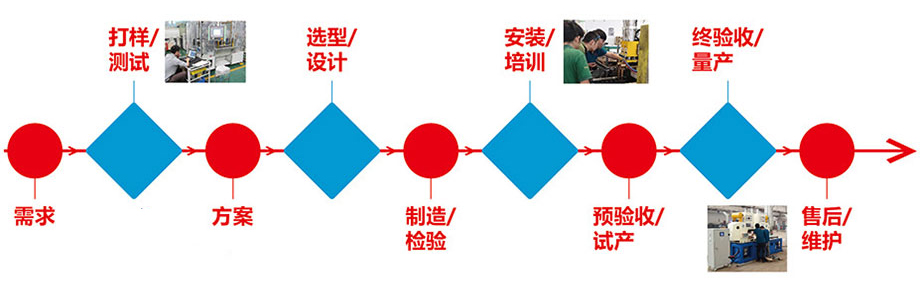

R&D CUSTOM PROCESS

Professional and attentive service, Radiant all the way to accompany!

Service System

Radiant's20-strong service team, 24h*7ervice online, 8h service to home, lifetime maintenance!

After-sales engineers come to the factory for free to install and debug, hand-hold training, to escort you!

GROUPED EQUIPMENT

Pressure Detector

Laser Power Meter

-

Advanced processing mode, high efficiency, low cost, fully automatic, easy to operate, easy to identify the product, in line with environmental requirements

-

Model

M30-CO2-D

M50-CO2-D

M100-CO2-D

Average Power

30W

50W

100W

Wavelength

10640nm

Laser Model

CO2

Frequency

5-100KHz

5-100KHz

5-100KHz

Minimum line width

0.1mm

0.1mm

0.1mm

Repeated accuracy

±2μm

±2μm

±2μm

Cooling

Water cooling Power Supply

800W(Two-phase)

1500W(Two-phase)

2200W(Two-phase)

Voltage Supply

220V±10%

-

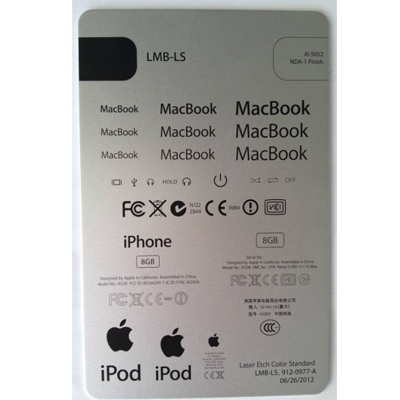

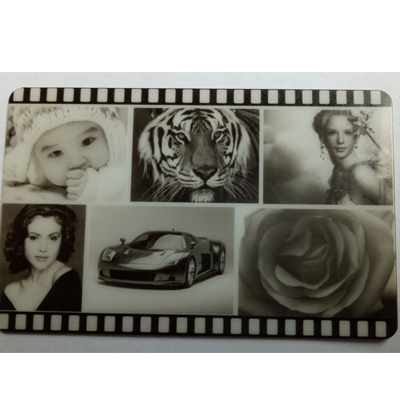

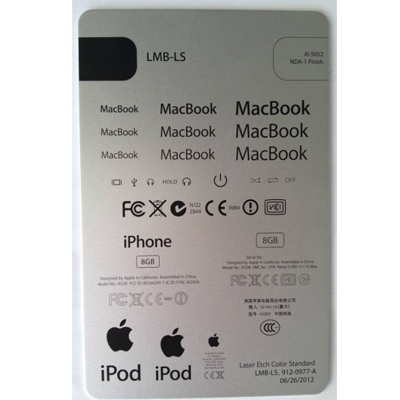

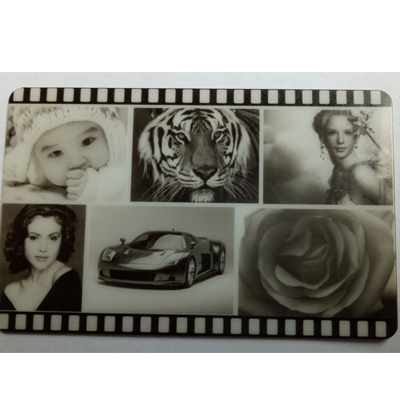

Widely used in food packaging, beverage packaging, pharmaceutical packaging, construction ceramics, clothing accessories, leather, buttons, fabric cutting, craft gifts, rubber products, stone, electronic components, cell phone casing, notebook and flat panel casing, stripping, film cutting, backlight board dotting, PCB barcode, casing nameplate, etc.