Product Center

UV laser marker

- Product Description

- Advantages

- Parameter

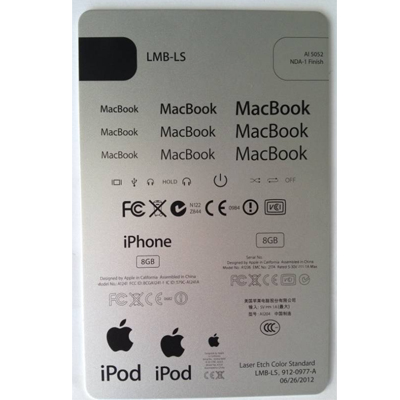

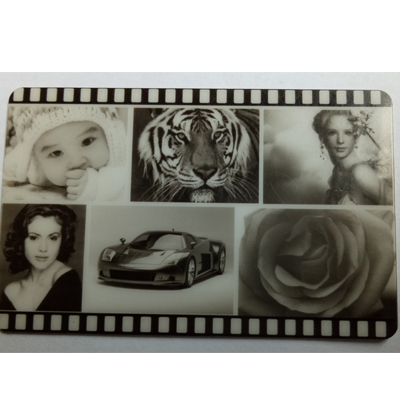

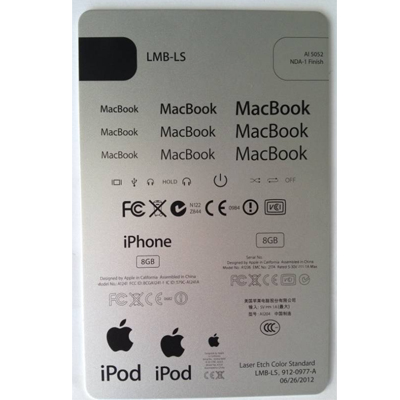

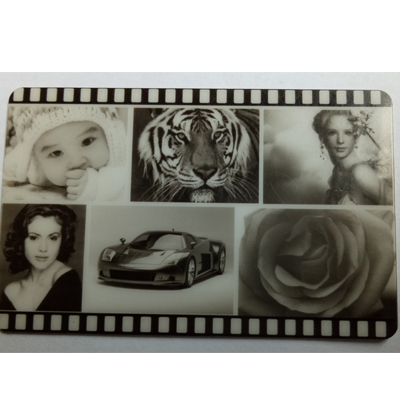

- Applications

-

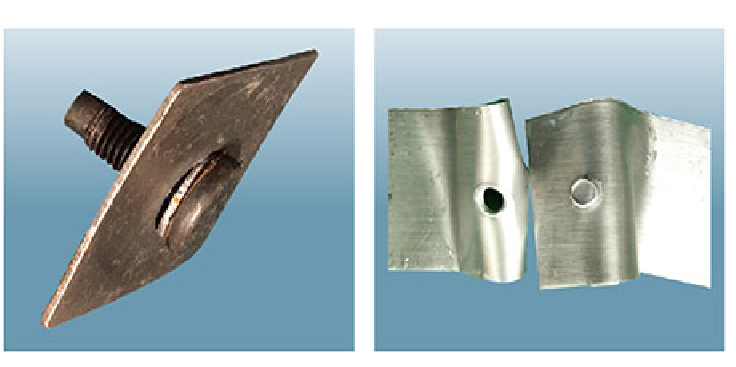

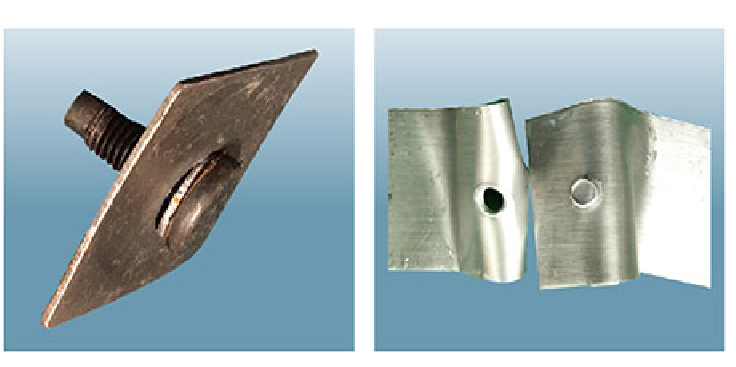

Welding Samples

Pull Test

Partner

Product Description

UV Laser Marking Machine

Semiconductor end pump laser marking machine is the use of international cutting-edge laser pumping technology, directly from the end of the laser crystal will be pumped into the semiconductor pump light (808nm), the output of the optical mirror group to produce laser. So that the laser light-light conversion efficiency is greatly improved, can reach more than 45%, while the pump source power consumption is also reduced, making the chiller power consumption dropped significantly, the machine power consumption reduced. End face pumping has better beam quality and higher peak power than side pumping.

M5-UV-Y

M8-UV-Y

01 High precision positioning sweep type oscillator

Scanning oscillator system, scanning laser oscillator is the core component of the marking machine, the performance of the marking machine mainly depends on the performance of the scanning laser oscillator, but also through this system to achieve the marking function.

02 Efficient air-cooled cooling

Laser marking machine cooling mode, cooling system is the entire laser machine can be stable and continuous marking premise, heat not only affects the laser out of escape, but also affect the circuit system, fiber laser marking machine through the air-cooled device to reduce the internal temperature of the body, while reducing machine failure, improve equipment stability, and has a small size and fast heat dissipation characteristics.

03 Up to 30% electro-optical conversion efficiency, economical and environmentally friendly.

Fiber laser, fiber laser with a more efficient design and the use of telecom-grade single-core junction pump source. Fiber lasers do not require adjustment of optics, maintenance-free or low-maintenance, fiber lasers are compact, smaller and easy to system integration

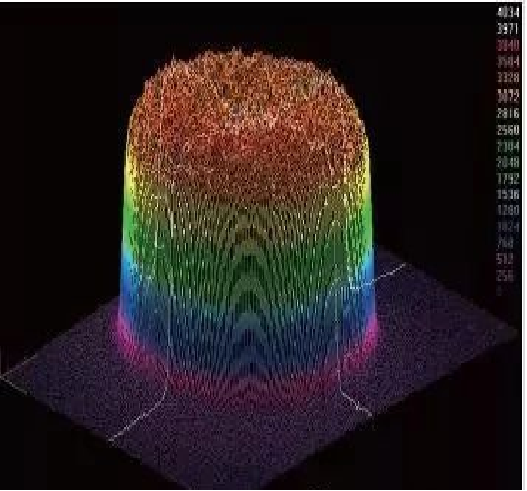

04 Flexibility of beam waveform

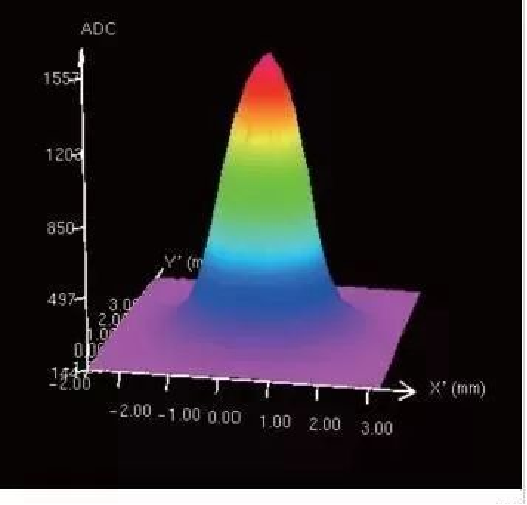

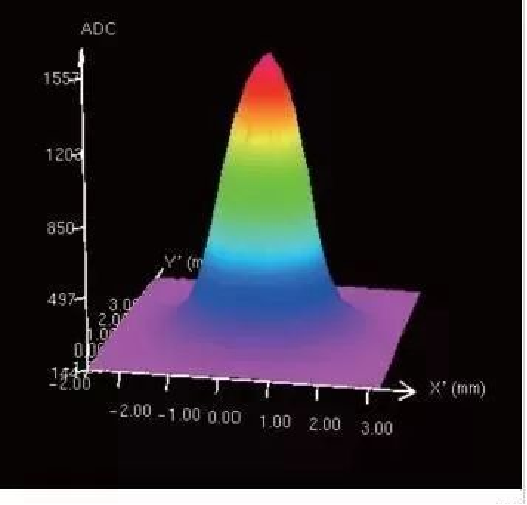

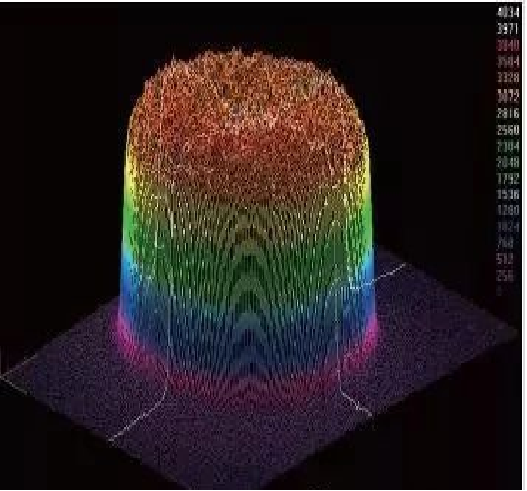

Fiber lasers are available with either single-mode or multi-mode output options. For cutting very thin materials or applications requiring a small spot size, single mode would be the appropriate choice. However, most high-power applications will use flat-top light or multimode modes (see illustration).

Core Component imported configiguration

Customized Project introduction

Huichuan Technologies 530 Product Marking Project Introduction

01 Customer background and pain points

Listed company huichuan technology company, is earlier engaged in electromechanical products enterprise, with the gradual popularization of new energy vehicles, more and more fuel engines are replaced by high-power motors, become a new generation of "engine", customers need to hit the engine number on the rough engine surface encountered the following problems: 1, efficiency is particularly low: one mold, one machine efficiency is low.

1, the efficiency is particularly low: a model of a machine efficiency is low.

2, marking depth is not up to standard: because the material is aluminum alloy, size and too large, resulting in insufficient depth.

The above two points customers are very distressed, has not been able to find a solution.

02 客户对设备要求高

汇川技术在2021年6月16日在网上找到我们,和我们的销售项目工程师讨论并想定制如下要求的焊机:

1、提高打标的效率;

2、提高打标机的利用率;

3、打标效率要求在原有的基础上提高30%以上;

4、成品率要在原有的基础上提高20%;

5、解决打标不稳定问题;

根据客户所提的要求,现有的标准打标机根本无法实现,怎么办?

03 客户根据客户要求,研发定制W150-F-J准连续激光焊接机

根据客户所提各项要求,公司研发部、焊接工艺部、销售部共同召开了新项目研发会议,一起探讨工艺、夹具、结构、馈电方式、配置,列出关键风险点、并逐个做出了解决方案,确定了基本方向和技术细节如下:

1、工件打样测试:镭扬打标机工艺师以最快的速度做了打样的简易夹具,用我们现有的激光打标机打样测试,经过双方5天的来回测试并做好拉拔检测,基本确定好焊接参数;

2、设备选型:研发工程师和焊接工艺师一起沟通并根据客户要求算出了选型功率,最后确认为M50-F-J2双头激光打标机;

3、设备的稳定性:我司采用核心部件全部"进口配置";

4、设备优势:

1)我们选择的双头激光打标机,一次型可摆放两个发动机,左边工位打标,右边工位上料,右边工位打标,左边工位又可以上料了,比原来的单头效率提高45%以上;

2)我们选用了特殊光源,解决了打标深度不足问题,成品率高,打标稳定,深度好,可达到1mm以上。

3)易操作,普通工人就可以操作,勿需专业焊工,节约了人工成本。

4)配合振镜头自动切换功能,打标效率在原有基础上可提高45%;

5)采用双振镜头打标机,成品率高,在原有的基础上可提高20%;

5、交货期:25个工作日。

04 高效设计、及时交货、专业服务、客户一致好评

在确定设备技术协议、签订合同后,镭扬的项目经理第一时间开生产项目启动会,确定了机械设计、电气设计、机械加工、外购件、装配、联调时间节点和客户来厂预验收、整改、总检和交货时间,并通过ERP系统有序的排发各部门工单、督促跟进各部门的工作进程。

很快35个工作日过去,汇川技术定制型汇川技术7130耳机双头点焊机经过老化试验完工了,经过我们专业的售后工程师在客户现场1天1夜的安装调试和技术、操作、维护培训,设备已正常投入生产并全部达到了客户的验收标准。汇川技术公司对该汇川技术发动机双头激光打标机实际生产和打标效果非常满意,帮他们解决了打标成品率问题、提高了打标效率、节省了人工,也给予我们高度认可和好评!

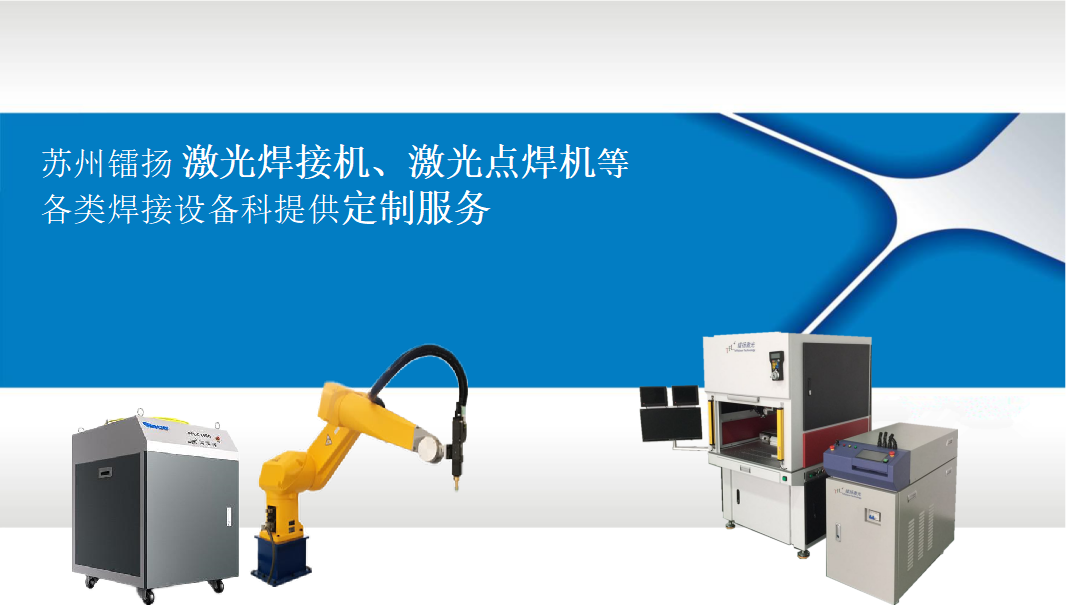

05 满足您的定制需求 是镭扬持续发展的使命

客户群是我们的导向,

您需要焊接什么材质的产品?

什么焊接要求?什么焊接工艺?

需要全自动的、半自动的、还是流水线?

任何问题请尽管提出来,镭扬都可以为您"定制研发"。

Customer cases

客户案例

安费诺耳机激光焊接产线

电池极耳自动焊接机

医疗器械激光焊接机

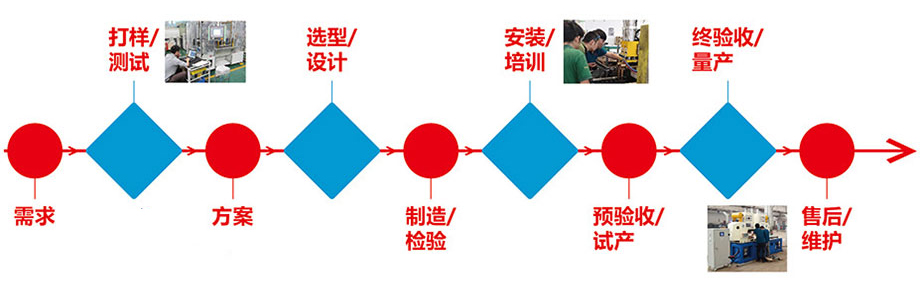

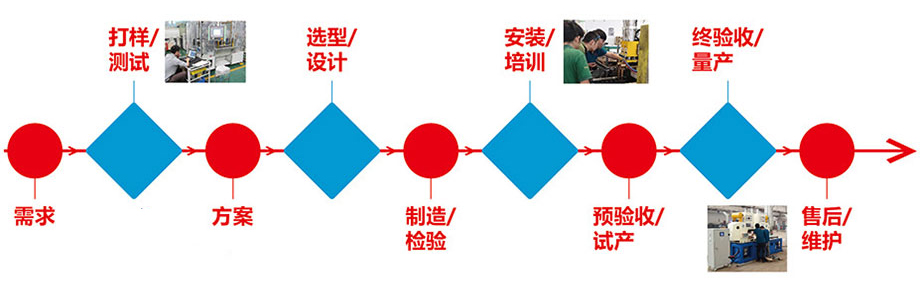

R&D CUSTOM PROCESS

研发定制流程

专业贴心的服务 , 镭扬一路陪伴!

Service System

客户服务体系

镭扬20多人的服务团队,24h*7服务在线,8h服务到家,终生维护!

售后工程师免费到厂安装调试,手把手培训,为您保驾护航!

GROUPED EQUIPMENT

配套设备

压力检测仪

激光功率计

拉力计

-

1. Provide safety protection cover to avoid personal injury caused by misoperation of equipment operators

2. It adopts imported Q-switch and high-speed galvanometer scanning system, with high peak laser power and fast scanning speed, which is suitable for laser precision marking and micromachining

3. Advanced hardware control technology and intelligent software provide customers with efficient and economical mass production and processing with simple operation and stable performance

4. The machine has stable performance, long service life and high electro-optic conversion rate. Low energy consumption, easy maintenance and cost saving, with a variety of laser types and equipment types, it is convenient for customers to choose different processing methods in different sites

-

Model

M3-UV-Y

M5-UV-Y

M8-UV-Y

M15-UV-Y

Average Power

3W

5W

8W

15W

Wavelength

355nm

Laser Model

LD pumped

Frequency

10-100KHz

10-100KHz

10-100KHz

10-100KHz

Pulse Width

23ns

23ns

25ns

25ns

Minimum line width

0.01mm

0.01mm

0.02 mm

0.02mm

Repeated accuracy

±2μm

±2μm

±2μm

±2μm

Cooling

water-cooling Power Supply

1200W(two phase)

1500W(two phase)

2200W(two phase)

3000W(two phase)

Voltage Supply

220V±10%

-

Medical devices, 3C industry, automobile industry, electronic components, electrical products, hardware tools, precision instruments, high and low voltage electrical appliances.