Product Center

QCW laser welder

- Product Description

- Advantages

- Parameter

- Applications

-

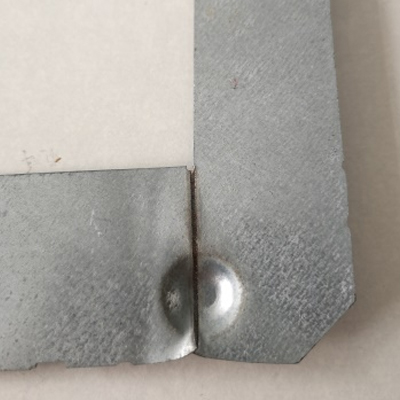

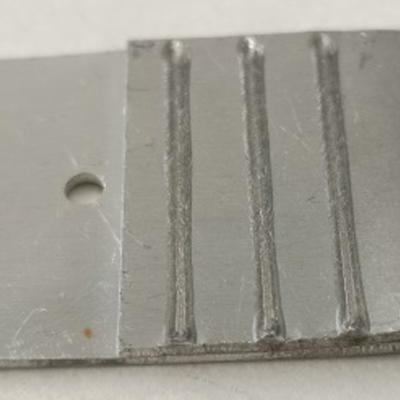

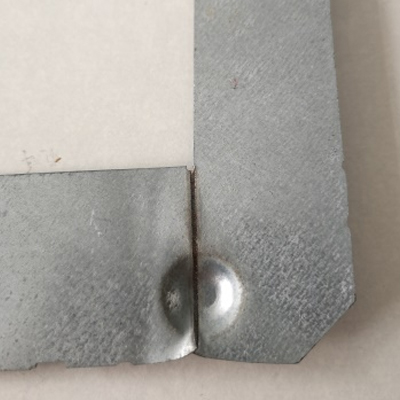

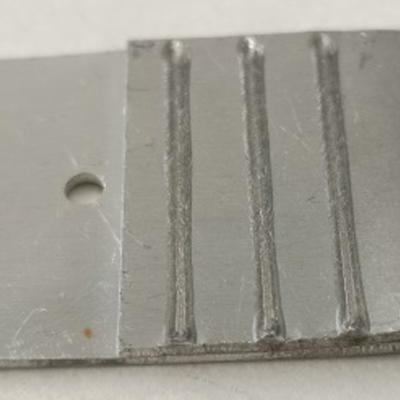

Welding Samples

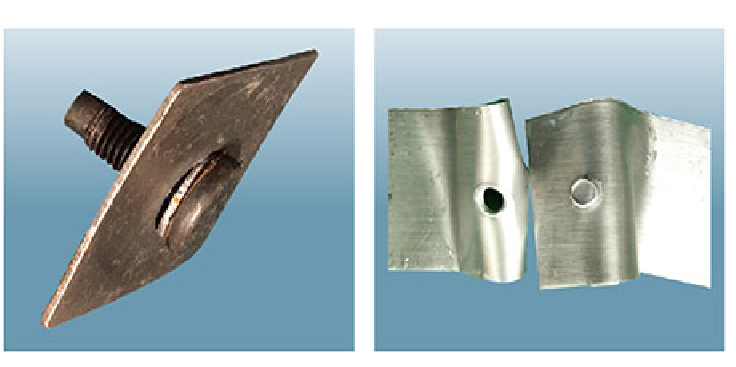

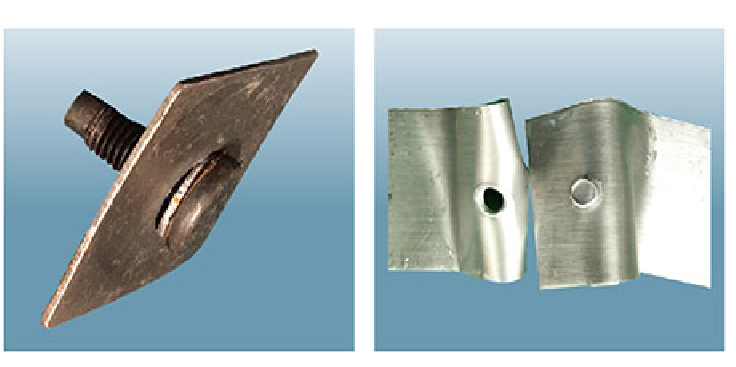

Pull Test

Partner

Product Description

W150-QCW-G quasi continuous laser welding machine

QCW is a quasi continuous fiber laser. It controls the continuous fiber laser in the way of pulse control to obtain the high peak power and laser energy of the pulse laser, and has the excellent beam quality of the fiber laser to achieve the best welding effect. It is one of the advanced welding methods at present

W150-QCW-G

W75-QCW-G

01 accurate D / a conversion, effectively inhibiting splash

Accurate D / a conversion and digital control of analog quantity make the nugget temperature rise continuously. At the same time, accurate current rise slope and time control will not cause heat jump and splash due to inability to control current rise time

02 peak power, high aspect ratio can be obtained, and high reverse materials such as copper and aluminum can be processed

The optical fiber core diameter can be selected from 20um to 50um. According to the power density formula, it can reach 10 times of the power density of ordinary optical fiber, which greatly improves the feasibility of welding high reflection materials.

03 up to 30% electro-optic conversion efficiency, economic and environmental protection;

QCW laser belongs to the category of fiber laser. The electro-optical conversion efficiency can be as high as more than 30%, which is much higher than the traditional YAG fiber conduction laser. It saves points and environmental protection, and greatly reduces the power consumption for long-term use,

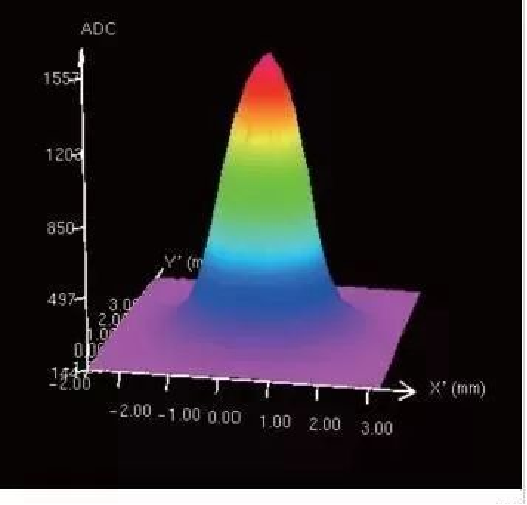

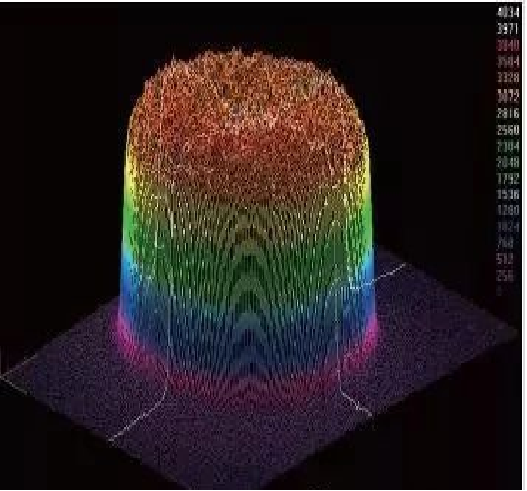

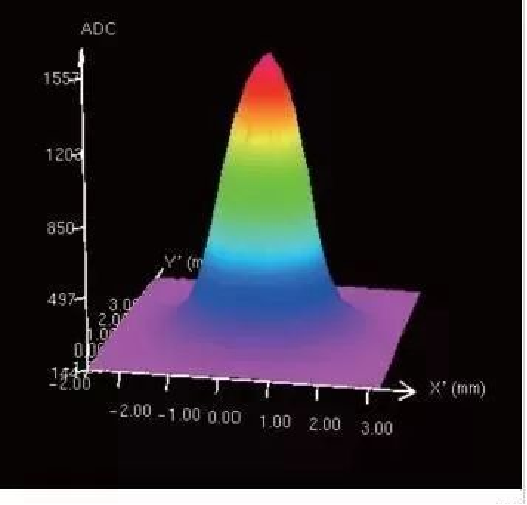

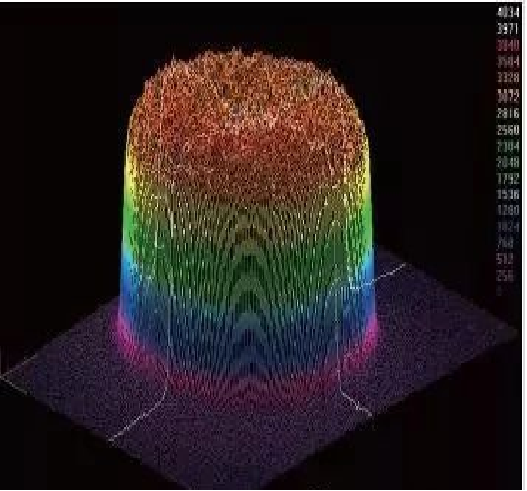

04 flexibility of beam waveform

Single mode or multimode output mode can be selected for QCW fiber laser. In order to cut very thin materials or applications requiring small spot size, single mode will be the appropriate choice. However, most high-power applications use flat top light or multimode mode (see Figure).

Core Component imported configiguration

Customized Project introduction

Tflamphenol 7130 earphone welding project introduction

01 customer background and pain points

Amphenol, a US funded enterprise, is an early manufacturer of communication devices and acoustic devices. It mainly focuses on injection molding, punching and welding. Most of the materials are copper. It is necessary to weld 0.1mm thick shrapnel and 0.8mm diameter copper column to increase the strength. The problems encountered are:

1. The welding efficiency is particularly low: the original process is single-sided and single point, and only one welding point can be welded at a time, so the efficiency is low;

2. The welding strength is not up to standard: the material is copper alloy and the size is too small, resulting in poor welding fastness;

The customer is very distressed about the above two points and has been unable to find a solution.

02 customers have high requirements for equipment

Amphenol found us online on October 16, 2019, discussed with our sales project engineer and wanted to customize the welding machine with the following requirements:

1. Improve welding efficiency;

2. Reduce the repair times of fixtures;

3, the welding efficiency requirement is increased by 50% on the original basis.

4. The yield should be increased by 30% on the original basis;

5. Solve the problem of welding instability;

According to the requirements of customers, the existing standard spot projection welding machine can not be realized at all. What should we do?

03 the customer developed and customized w150-f-j quasi continuous laser welding machine according to the customer's requirements

According to various requirements put forward by customers, the company's R & D department, welding process department and sales department jointly held a new project R & D meeting to discuss the process, fixture, structure, feeding mode and configuration, list the key risk points, make solutions one by one, and determine the basic direction and technical details as follows:

1. Workpiece proofing test: Rayon welding technologist made a simple fixture for proofing at the fastest speed. We used our existing medium frequency welder for proofing test. After 5 days of back and forth test and drawing test, the welding parameters were basically determined;

2. Equipment selection: the R & D Engineer communicated with the welding technologist, calculated the selection power according to the customer's requirements, and finally confirmed it as w150-qcw-j2 earphone double head spot welder;

3. Stability of equipment: our company adopts "imported configuration" of all core components;

4. Equipment advantages:

1) The double head automatic spot welder we choose can weld two spots at one time, which is more than 50% higher than the original single spot efficiency;

2) We have selected special electrode materials to solve the phenomenon of burst point, with high yield, stable solder joint and high strength, which can reach the strength of base metal. After welding, the solder joint can be directly pulled through the base metal;

3) Easy to operate, ordinary workers can operate without professional welders, saving labor costs.

4) With automatic displacement tooling, the welding efficiency can be increased by 50% on the original basis;

5) Using double vibrating lens welding, the yield is high, which can be increased by 30% on the original basis;

5. Delivery date: 25 working days.

04 efficient design, timely delivery, professional service and unanimous praise from customers

After determining the equipment technical agreement and signing the contract, the project manager of rayon held the production project kick-off meeting at the first time, determined the time nodes of mechanical design, electrical design, machining, purchased parts, assembly and joint commissioning, as well as the time for customers to come to the factory for pre acceptance, rectification, general inspection and delivery, and orderly arranged the work orders of each department through the ERP system Supervise and follow up the work progress of each department.

Soon after 35 working days, the Amphenol customized Amphenol 7130 earphone double head spot welding machine has been completed through aging test. After our professional after-sales engineer's installation, commissioning and technical, operation and maintenance training at the customer's site day and night, the equipment has been put into production normally and fully met the customer's acceptance standards. Amphenol company is very satisfied with the actual production and welding effect of the Amphenol 7130 earphone double head spot welder. It helps them solve the problem of welding yield, improve welding efficiency and save labor. It also gives us high recognition and praise!

05 to meet your customized needs is the mission of rayon's sustainable development

Customer base is our orientation,

What material do you need to weld?

What welding requirements? What welding process?

Do you need fully automatic, semi-automatic or assembly line?

Please feel free to ask any questions. Rayon can "customize R & D" for you.

Customer cases

Amphenol earphone laser welding production line

Battery lug automatic welding machine

Medical instrument laser welding machine

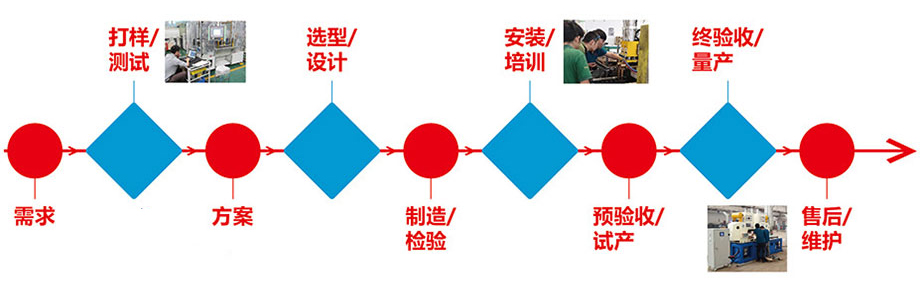

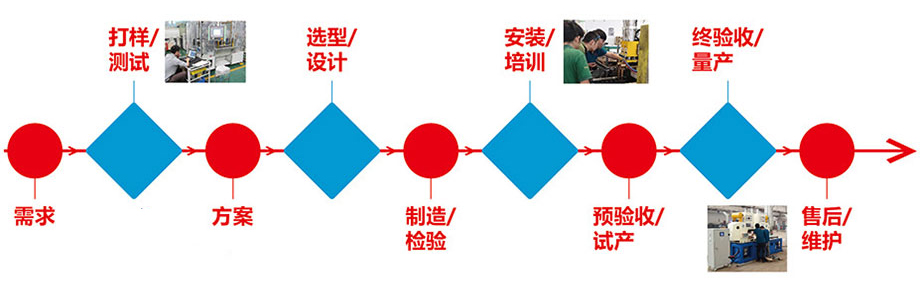

R&D CUSTOM PROCESS

Professional and considerate service, accompanied by radium Yang all the way!

Service System

Radium Yang's service team of more than 20 people, 24h*7service online,8h service home, lifelong maintenance!

After sales engineers go to the factory for installation and commissioning free of charge, hand-in-hand training, and escort you!

GROUPED EQUIPMENT

Pressure detector

Laser power meter

tensimeter

-

1. Constant beam quality in the full power range;

2. All fiber structure maintenance free;

3. Superior output power / energy stability;

4. High peak power, can process copper, aluminum and other high reverse materials;

5. Up to 30% electro-optic conversion efficiency, economic and environmental protection;

6. Compact structure and forced air cooling.

-

Model

W80-QCW-J

W150-QCW-J

W300-QCW-J

W600-QCW-J

Average Power

80W

150W

300W

600W

Wavelength

1064nm

Laser Model

ptical fiber Max Pulse Energy

10J

15J

30J

60J

Pulse Width

0-20ns

0-20ns

0-20ns

0-20ns

Beam Size

0.01-0.08mm

0.01-0.08mm

0.02-0.08mm

0.03-0.08mm

Welding Depth

1mm

2mm

3mm

5mm

Cooling

Air cooling Air cooling Air cooling Air cooling Power Supply

300W(two phase)

500W(two phase)

1000W(two phase)

2000W(two phase)

Voltage Supply

220V±10%

220V±10%

220V±10%

220V±10%

-

Medical devices, consumer electronics industry, sensor parts, aerospace, new energy lithium batteries, fuel cells and other precision products